Wave Soldering

Wave Soldering

Wave soldering is a soldering process used in the manufacture of printed circuit boards. It gains its name from the fact that the process passes the printed circuit boards to be soldered over a wave of solder.

Wave soldering process is composed of four steps: flux spraying, pre-heating, wave soldering and cooling.

Step one – Flux Spraying: Flux main function is to remove the oxide layer on PCBs enabling a clean metal surface for the solder joints. At this stage, the flux is sprayed from the machine’s flux sprays to the bottom of the PCBs ensuring that the soldering process has the required proper performance.

Step two – Pre-heating: The electronic printed circuit boards exposed to considerable levels of heat. Pre-heating helps to overcome thermal shock. So electronic board can be steadily brought up to the required temperature, which minimize any thermal shock.

The preheating area normally uses hot air heaters that blow hot air onto the boards as they pass towards the wave soldering machine. On some occasions, particularly if the board is densely populated, infra-red heaters may be used as well. This ensures that all the board is evenly heated and no shadow areas are present.

Also pre heating is necessary to activate the flux. Flux is required to ensure that the areas to be soldered are clean and will take the solder.

Step three – Wave Soldering: Once the board is at reasonable temperature, the printed circuit board passes over a molten wave of solder alloy generated by soldering nozzles. This is the step in which the soldering process takes place and the components are being soldered on the PCBs.

Step four – Cooling: It is important that the PCBs allowed to cool at a reasonable rate. If they are cooled too fast, then the PCB can become warped and the solder can be compromised. On the other hand, if the PCB is allowed to cool too slowly, then the PCB can become brittle and some components may be damaged by heat.

Wave soldering, also known as flow soldering, is normally performed in a protective gas atmosphere since the use of nitrogen offers an opportunity to reduce solder defects.

Wave soldering is used for both through-hole printed circuit assemblies, and surface mount. Apart from being much faster than manual soldering, wave soldering also produces joints with a much higher degree of reliability and this makes it ideal for large scale PCB assembly.

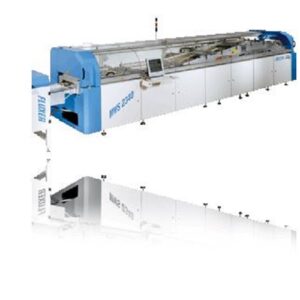

Seho offers most innovative machine techniques for small, medium or large production volumes.

Showing all 5 results