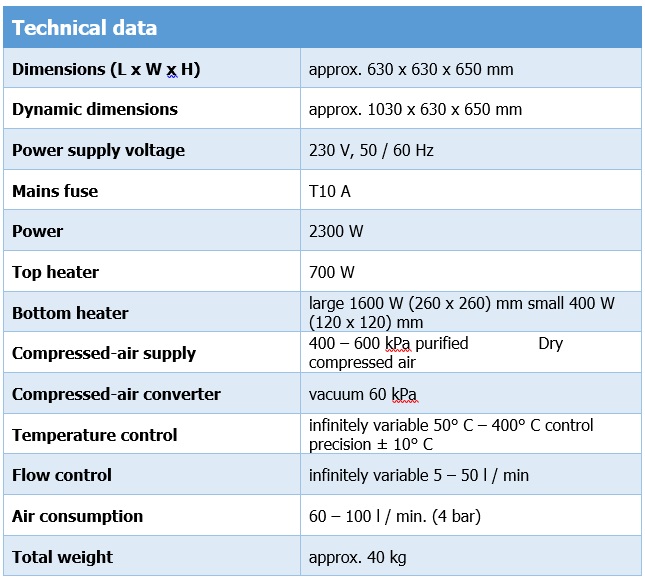

WQB 4000SOPS Repair and Rework station

WQB 4000SOPS Repair and Rework station

WQB 4000SOPS – The next generation For unmatched precision & functionality

Maximum precision. Maximum flexibility. Maximum user-friendliness.

WQB 4000SOPS Repair and Rework station combines a completely new design with state-of-the-art split optic camera technology to provide users with absolute reliability, optimum process control and enhanced ease of use.

The system was engineered to bring together a finely tuned balance of automated technology for component pick-up and positioning with a semi-automated rework cycle – opening up new possibilities and applications in repair and rework.

Well considered detail, high-precision results and an outstanding price-performance ratio promise to make this new system from Weller the first choice among discerning users.

Advanced design for enhanced

precision The WQB 4000SOPS is modularly built with a slide platform, advanced patented systems and materials of the highest quality to guarantee industrial reliability and long-lasting durability.

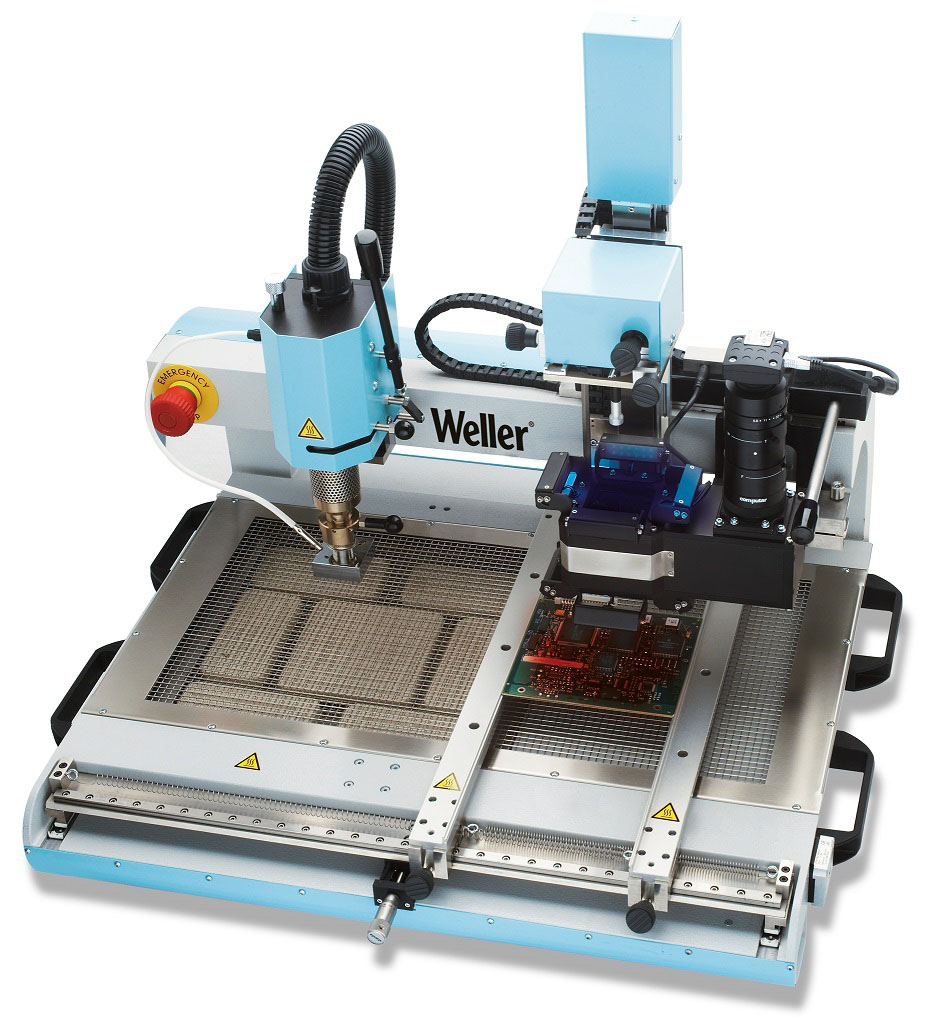

Heating from above: selective and sensitive

The hot gas heater with patented nozzle system, coupled with digital control electronics for temperature monitoring and regulation of the air flow rate, facilitates the finely metered supply of heat to the components. A temperature sensor placed directly in the hot gas nozzle prevents thermal overload of the component and efficiently regulates the top heater, providing maximum process control.

Heating from below: rapid and homogeneous

The temperature-regulated two-zone infrared bottom heater provides rapid, yet precisely controlled warm-up at homogeneous substrate temperatures.

Streamlined technology

The new WQB 4000SOPS enables users to work with a standard PC via a USB 2.0 port. Additional appliances or interface cards are not required.

Cleaning of the circuit board

Residual solder should be removed from the board with a desoldering iron or desolder wick. Residual contaminants can be removed with a suitable solvent spray.

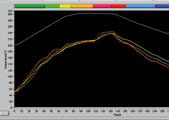

Monitoring software:

comprehensive functions The monitoring software determines temperature profiles and facilitates definition of the optimal soldering process.

Positioning of the new component

The new WQB 4000SOPS station’s split optic camera placement system ensures precise positioning of a wide range of components – from BGA to fine pitch SMT.

Everything about the new WQB 4000SOPS

has been engineered and designed for ease of use and superb results – from its advanced, user-friendly software all the way through to its many supportive details, such as the SoftStart feature

Teach-in feature: fast, effective

parameter identification Repeatable results can only be achieved by a process cycle that considers all the parameters of the repair operation.

The ‘Teach-in’ feature provides a quick and easy method of determining process cycle parameters and identifying critical points – without the need for in-depth operator knowledge. The software includes a library of soldering profiles, i.e. general and specific parameters enabling repeatable use. New profiles can be edited easily by the user and added to the library.

Perfect component /circuit board alignment

With the split optic camera, live images of a component and a circuit board can be aligned independently of each other using the x, y and theta

axis fine adjustment drives.

1. Component size & theta axis

2. Align y axis

3. Align x axis

4. Component aligned!

An ever expanding field of applications

The new WQB 4000SOPS is optimally equipped to take on repair and rework in mobile communications, research and general BGA/QFP work.

Specifically, with PBGA, CBGA, CCGA, CSP’s, Micro BGA, QFN, PLCC, SOP and PGA components.

1. Components without direct access to the solder joint

2. Leaded components with external solder joints

3. A wide variety of special modules

Removal (desoldering) of the defective component

The ability to preheat the circuit board and a temperature/time controlled process are critical for good reflow of the solder joints. At the end of the reflow cycle, to avoid damage to the solder pads, a vacuum lift automatically removes the component from the board with minimum force and exact temperature control.

As on-board components become increasingly complex, Weller continues to lead the field with innovative, user-friendly repair and assembly tools that enable users to successfully take on increasingly demanding rework challenges.

The new WQB 4000SOPS (Split Optic Positioning System), the third generation of the Weller BGA/SMT repair system, is engineered to meet the exceptional demands placed on modern rework tools and designed to deliver real value for your investment.

It is a comprehensive, user-friendly system for the removal and soldering of BGA components, without the risk of thermal damage to the component or circuit board.

Split Optics for perfectly accurate positioning

The new SOPS (Split Optic Positioning System) with the high-resolution 2 Mpix CMOS USB 2.0 camera enables accurate positioning of the components following desoldering. It works with a single camera and two-color lighting for exact positioning. Superb image quality at high dynamics and very low image noise ensure precise, ergonomic component mounting.

Component soldering

Reflow of the replaced component is essentially a repeat of the removal process, without the vacuum lift being initiated at the end of the profile.

An extensive range of hot gas nozzles and adapters are available to cater for the many body sizes of BGA devices or QFP and PLCC packages.

Component soldering

Reflow of the replaced component is essentially a repeat of the removal process, without the vacuum lift being initiated at the end of the profile.

An extensive range of hot gas nozzles and adapters are available to cater for the many body sizes of BGA devices or QFP and PLCC packages.

To complete your program you can find details of our wide range of WQB accessories including reflow nozzles, temperature sensors and working appliances in our price list and on the Weller web site: www.weller.de