Soldering Flux

When solder melts and forms a joint between two metal surfaces, it actually forms a metallurgical bond by chemically reacting with the other metal surfaces.

A good bond requires two things, a solder that is metallurgic ally compatible with the metals being bonded and good metal surfaces, free of oxides, dust, and grime that prevent good bonding. Grime and dust can easily be removed by cleaning or prevented with good storage techniques. Oxides, on the other hand need another approach.

Oxides form on almost all metals when oxygen reacts with the metal. On iron, oxidation is commonly called rust, but it happens to tin, aluminum, copper, silver, and nearly every metal used in electronics. Oxides make soldering much more difficult or even impossible, preventing a metallurgical bond with the solder. Oxidization happens all of the time, but happens much faster at higher temperatures, like when soldering Flux cleans metal surfaces and reacts with the oxide layer, leaving a surface primed for a good solder bond. Flux remains on the surface of the metal while soldering which prevents additional oxides from forming due to the high heat of soldering.

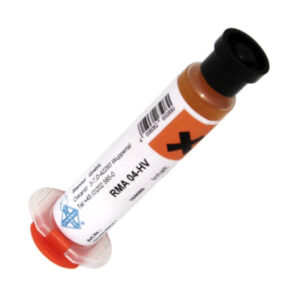

As with solder, there are several types of solder, each with key uses and some limitations as well.

Types of Flux: Rosin Flux, Organic Acid Flux, Inorganic Acid Flux, Solder Fumes, Flux Gel, Flux Pen, Flux Liquid, Electronic Flux, Quick Flux

Showing all 5 results