Soldering Pastes

Solder paste is an alloy or unalloyed metal which, when heated, liquefies and melts to flow into the space between two close fitting parts, creating a soldered joint. Solder paste has suitable melting and flow properties to permit distribution by capillary attraction in properly prepared joints. Solder pastes produce joints that meet service requirements, such as strength and corrosion resistance. They also meet the specifications of the American Welding Society (AWS), The American Society for Testing Materials (ASTM), and in nearly all cases, ISO standards as well.

Pastes products consist of an atomized filler metal powder, a flux (when necessary) and a binder to hold the components together in suspension. Pastes, like preforms, are advantageous because with the correct dispensing equipment, tight control can be made on material usage. And because pastes are essentially formless in nature, one paste product could be suitable for a wide variety of joint configurations.

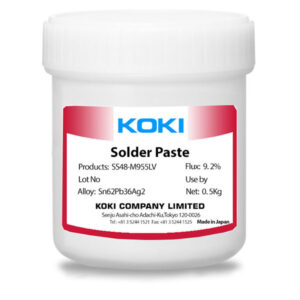

Standard solder paste includes tin, lead, silver, lead-free, sil-phos, copper, aluminum, nickel, and jewelers gold. Fusion solder paste consists of finely atomized filler metal alloy blended with flux and a paste-like binder.

Solder paste delivers all the ingredients for a strong, void-free joint in one deposit. Stored in a pressurized reservoir, the solder paste is dispensed automatically in pre-measured amounts.

Showing all 8 results