Hand-held Clutch Screwdrivers /KBL Series

KBL Brushless Screwdrivers | Torque range 0.04 − 4 Nm

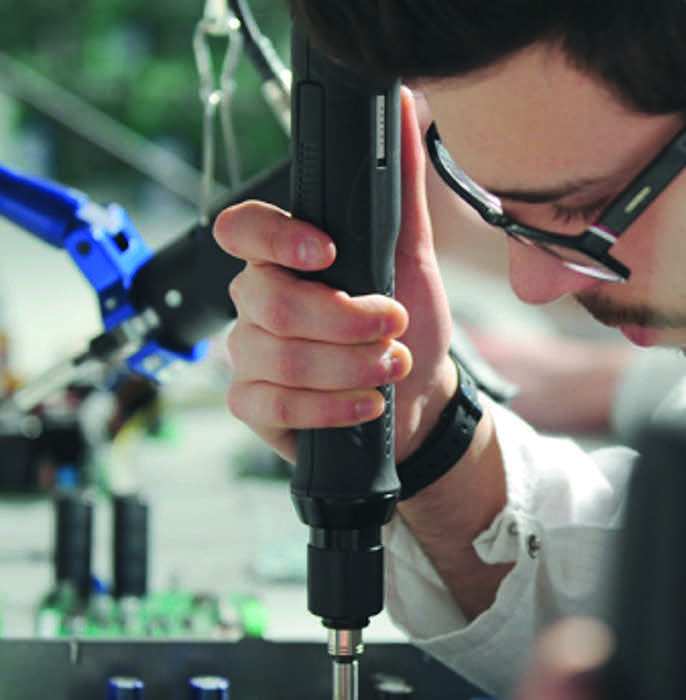

The perfect solution for clean room applications. KBL screwdrivers feature state-of-the-art brushless motors and clutch torque control

Simple set up

KBL tools are very easy to install and operate. The torque is set externally: you’ll only have to manually adjust the front clutch according to the required torque setting. Each screwdriver works in combination with a control unit. Its electronic control circuit cuts the power supply to the screwdriver motor in response to the clutch action, as soon as the pre-set torque has been reached.

Maintenance-free

No wearing components and no brush replacement – KBL Screwdrivers combine Swiss brushless motors with magnetic clutch switches for a real maintenance-free solution. The absence of maintenance operations guarantees high productive continuity. EDU1BL control units for KBL screwdrivers feature state-of-the-art electronics working at only 30 VDC. This design results in very low current to the driver’s start and clutch switches to extend their life even further.

For a cleaner environment

No brushes means zero emissions of carbon dust or other pollutants into the working environment, which makes KBL screwdrivers perfect for clean-room applications.

Safe and ergonomic

KBL hand-held screwdrivers are available in inline and pistol type and they all come standard with ESD-safe housing. Small and lightweight for utmost operator comfort and with advanced ergonomic design, they ensure very low noise level, minimum vibrations ESD safe housing and maximum safety.

Improve your productivity by cutting investments

It is possible to use two screwdrivers with just one control unit by connecting a double output device called DOCK 02 (for KBL FR) or DOCK 02/S (for KBL FR/S). The two screwdrivers can be used at the same time for maximum productivity. 230V only.

INLINE – Inline versions available in lever start with signals (KBL FR/S) or without (KBL FR).Also available with auto reverse feature (KBL FR/AR), best used with RIV HD riveting heads. Bit Drive: 1/4″ hex quick change chuck.

PISTOL GRIP – Trigger start, pistol grip available with signals (KBL P/S) or without (KBL P/FR). Bit Drive: 1/4″ hex quick change chuck.

ANGLE HEAD OPTION – 90° angle heads can be easily attached to inline models. Angle attachments ar the ideal solution to operate where space is limited.

Inline KBL Screwdrivers

| Code | Model | Torque Nm | RPM min-max | Dimensions mm | Weight kg | control unit |

| Standard models 190004 | KBL04FR | 0.04 – 0.4 | 700 – 1150 | 255 x 37 | 0.50 | EDU1BL |

| 190015 | KBL15FR | 0.4 – 1.5 | 700 – 1150 | 255 x 37 | 0.50 | EDU1BL |

| 190030 | KBL30FR | 0.7 – 3 | 700 – 1150 | 268 x 43 | 0.65 | EDU1BL |

| 190040 | KBL40FR | 0.9 – 4 | 400 – 700 | 268 x 43 | 0.65 | EDU1BL |

| Models with I/O signals 190004/S | KBL04FR/S | 0.04 – 0.4 | 700 – 1150 | 255 x 37 | 0.50 | EDU1BL/SG |

| 190015/S | KBL15FR/S | 0.4 – 1.5 | 700 – 1150 | 255 x 37 | 0.50 | EDU1BL/SG |

| 190030/S | KBL30FR/S | 0.7 – 3 | 700 – 1150 | 268 x 43 | 0.65 | EDU1BL/SG |

| 190040/S | KBL40FR/S | 0.9 – 4 | 400 – 700 | 268 x 43 | 0.65 | EDU1BL/SG |

Pistol grip KBL Screwdrivers

| Code | Model | Torque Nm | RPM min-max | Dimensions mm | Weight kg | Control unit |

| Standard models 190005 | KBL04P/FR | 0.04 – 0.4 | 700 – 1150 | 154 x 210 x 45 | 0.50 | EDU1BL |

| 190016 | KBL15P/FR | 0.4 – 1.5 | 700 – 1150 | 154 x 210 x 45 | 0.50 | EDU1BL |

| 190031 | KBL30P/FR | 0.7 – 3 | 700 – 1150 | 154 x 217 x 45 | 0.65 | EDU1BL |

| 190041

Models with I/O signals 190005/S |

KBL40P/FR

KBL04P/S |

0.9 – 4

0.04 – 0.4 |

400 – 700

700 – 1150 |

154 x 217 x 45

154 x 210 x 45 |

0.65

0.50 |

EDU1BL EDU1BL/SG |

| 190016/S | KBL15P/S | 0.4 – 1.5 | 700 – 1150 | 154 x 210 x 45 | 0.50 | EDU1BL/SG |

| 190031/S | KBL30P/S | 0.7 – 3 | 700 – 1150 | 154 x 217 x 45 | 0.65 | EDU1BL/SG |

| 190041/S | KBL40P/S | 0.9 – 4 | 400 – 700 | 154 x 217 x 45 | 0.65 | EDU1BL/SG |

Angle head KBL Screwdrivers

| Code | Model | Torque Nm | RPM min-max | Dimensions mm | Weight kg | Control unit |

| 190004/A | KBL04FR/ANG | 0.04 – 0.4 | 700 – 1150 | 316 x 37 | 0.60 | EDU1BL |

| 190015/A | KBL15FR/ANG | 0.4 – 1.5 | 700 – 1150 | 316 x 37 | 0.60 | EDU1BL |

| 190030/AD | KBL30FR/ANG | 0.7 – 3 | 700 – 1150 | 330 x 43 | 0.75 | EDU1BL |

| 190040/AD | KBL40FR/ANG | 0.9 – 4 | 400 – 700 | 330 x 43 | 0.75 | EDU1BL |

Control units for KBL Screwdrivers

| Code | Model | Settable Speed | Ramp Option | I/O Signals | Serial Print | Screw Count | Min-Max Run Time | Weight kg | Dimensions mm |

| 003000 | EDU1BL | . | – | – | – | – | – | 0.60 | 138 x 118 x 67 |

| 003000/SG | EDU1BL/SG | . | . | . | with ACE | with ACE | with ACE | 0.60 | 138 x 118 x 67 |