Halogen-free Solder Paste for Laser Soldering

S3X58-M330D Sn 3.0Ag 0.5Cu

Increasing Demand for Laser Soldering

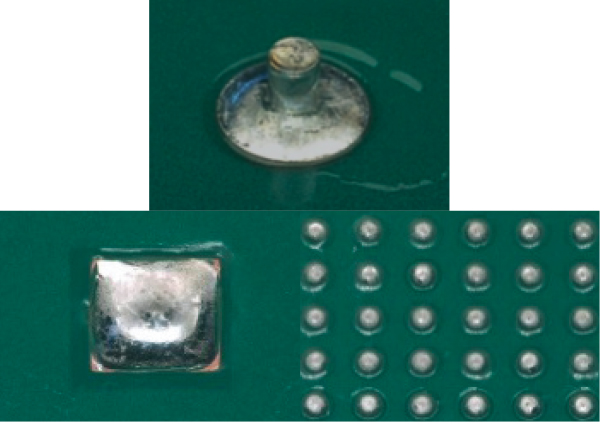

Demand for laser soldering is increasing especially for consumer product market in camera modules and connector pins. Since the laser soldering can be completed without the laser actually touching component, it can not only avoid heavy thermal stresses but also the temperature variance.

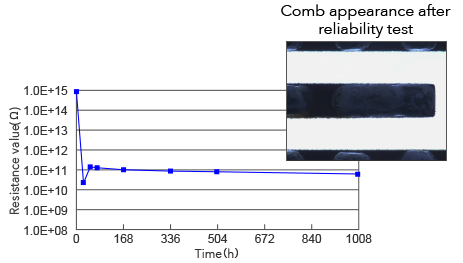

Maintains Insulation Resistance Over 109Ω

In general, laser soldering is associated with loss of insulation resistance as instantaneous heating may cause the solvent inside the flux to remain active even after soldering. S3X58-M330D displayed no evidence of dendritic growth or ionic migration occurrence after insulation resistance test under bias voltage (85˚C/85%RH, 1000 hrs, bias voltage 50V).

Product Performance Table

| Product Name | S3X58-M330D | Product Category | Solder Paste | |

| Composition |

|

Melting Point(℃) | 217-219 | |

| Particle Size(μm) | 20-38 | Viscosity(Pa.s) | 100 ± 20 | |

| Halide content(%) | 0 | Flux Type | ROL0 (IPC J-STD-004B) |