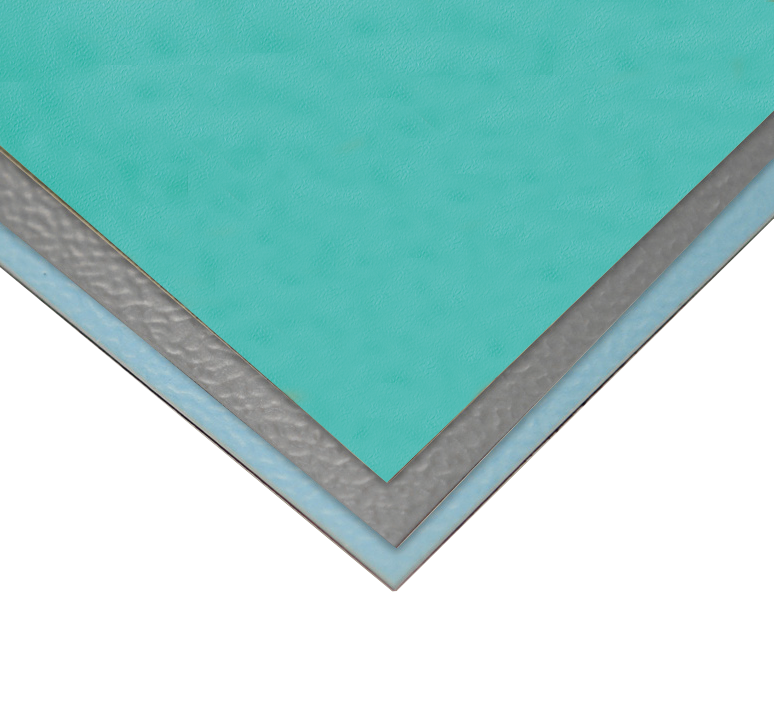

ESD 2 LAYERS TABLE MATS TEXTURED FINISH

ESD 2 layers table mats should be laid out in the workshops or advanced laboratories for microelectronic industries such as electronic semi-conduct devices, electronic computers, electronic communication equipment and integrated circuits etc.

Grounding

Sufficient ground cords should be used to reliably meet EN 61340-5-1 Table 3 less than 1 x 109 ohms for working surfaces. Industry recommendation is that continuous runs of ESD matting should be grounded at 10ft intervals to allow proper charge decay rates. Each individual ESD mat should be grounded with ground snaps located no further than five feet from either end.

Cleaning

Please note that contact between the matting surface and any acid or alkali solvent is strictly prohibited (such as Benzene, Alcohol etc.), this will result in the antistatic performance wearing away. If cleaning is required, the matting may be wiped with a cloth coated in a neutral solution (such as water).

| ART No. | DESCRIPTION |

| M3000B07 | ESD MAT 600 x 1000 MM 2 x STUD 10MM BLUE |

| M3000B09 | ESD MAT 600 x 900 MM 2 x STUD 10MM BLUE |

| M3000B12 | ESD MAT 600 x 1200MM 2 x STUD 10MM BLUE |

| M3000G07 | ESD MAT 600 x 1000MM 2 x STUD 10MM GREY |

| M3000G09 | ESD MAT 600 x 900MM 2 x STUD 10MM GREY |

| M3000G12 | ESD MAT 600 x 1200MM 2 x STUD 10MM GREY |

| M300B121 | ESD MAT 1000 x 1200MM 2 x STUD 10MM BLUE |

| M300G121 | ESD MAT 1000 x 1200MM 2 x STUD 10MM GREY |

| M300S120 |

ESD-TABLE MATTING ROLL 1.2 x 10 METER GREEN |

| M3000B08 | ESD TABLE MATTING ROLL 0.8 X 10 METER TEXTURED BLUE |

| M3000G08 | ESD TABLE MATTING ROLL 0.8 X 10 METER TEXTURED GREY |

| M300B120 | ESD-TABLE MATTING ROLL 1.2 X 10 METER TEXTURED BLUE |

| M300G120 | ESD-TABLE MATTING ROLL 1.2 X 10 METER TEXTURED GREY |