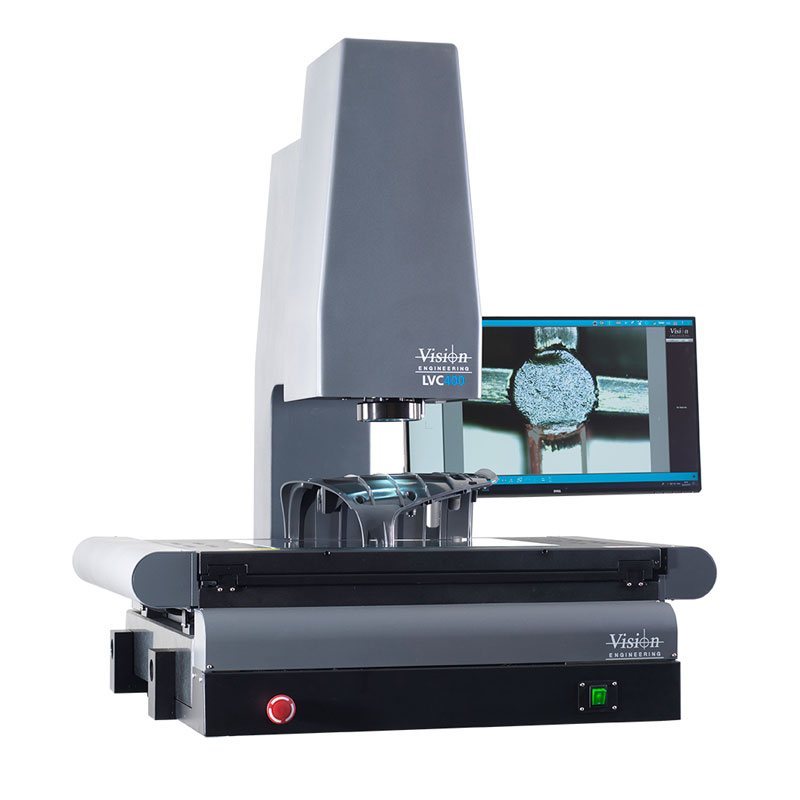

Automated Measurements in 3 Axes

Lengthy measurement routines are often a big problem for manufacturers. Reducing measurement time, without compromising product quality is a critical factor in the continuous improvement of the manufacturing process.

LVC400 has the power and flexibility to meet the most demanding measurement requirements and suits industry applications including precision machining, casting, plastic mouldings, electronics and medical device.

Highlights

- Measure components up to 400mm x 300mm x 200mm

- Great video image with 5MP USB3.0 camera

- Motorised zoom lens for automatically changing magnification in measurement routines.

- Intuitive M3 software maintains ease of use despite advanced functionality of the system.

- Granite base for extra stability and measuring accuracy.

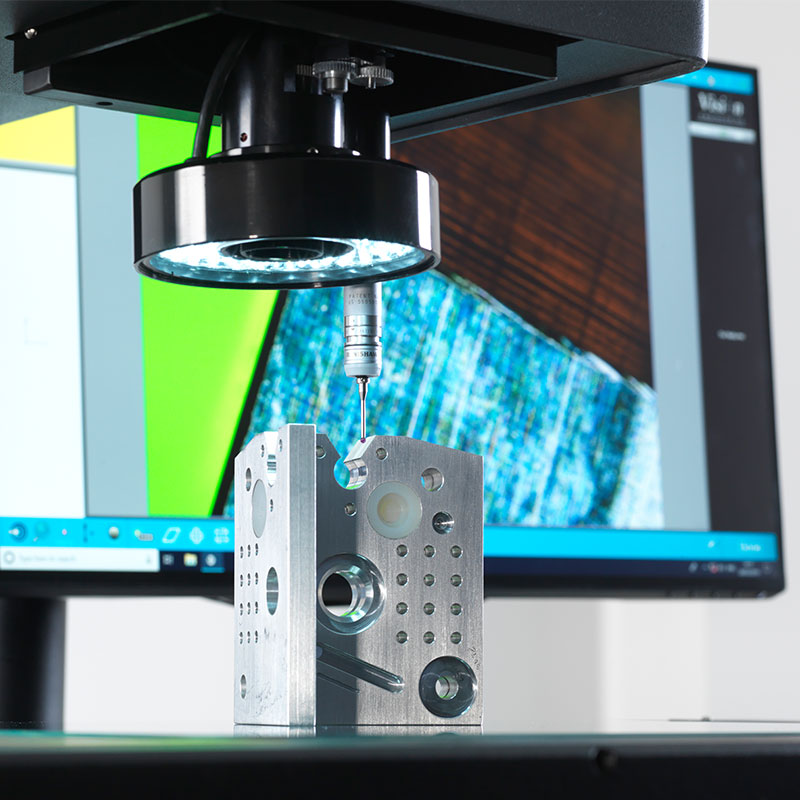

- Touch probe option for measuring complex features and 3D forms, such as cylinders, cones and spheres.

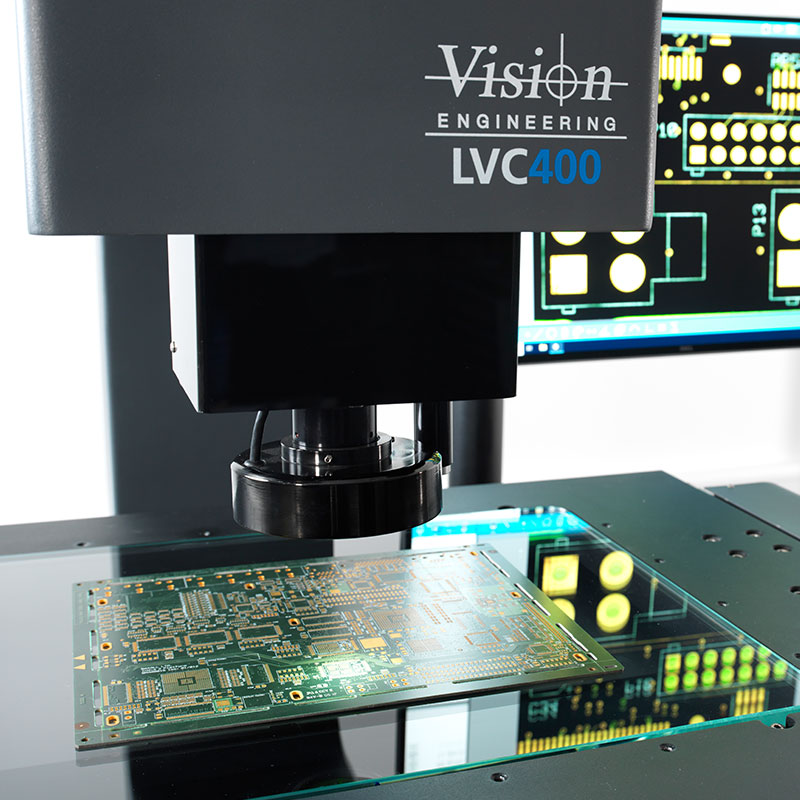

- Ideal for a wide range of applications including precision engineering, casting, plastic moulding, electonics and medical devices manufacture.

Faster Measurement : reducing time and saving costs

Reducing measurement time, without compromising product quality is a critical factor in the continuous improvement of the manufacturing process.

Large components may take quite a long time to measure on manually operated measuring systems. The LVC400 is equipped with a motorised measuring stage and motorised zoom lens to automate the movement of the system and reduce measurement time as well as discomfort to operators.

The 6-position motorised zoom lens allows magnification changes to be included in the measurement program without the need for an operator to manually change magnification during measuring routines.

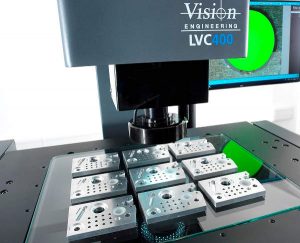

LVC400 is ideal for measuring large components, but can also be used to speed up measurement of smaller components. The palletising feature enables operators to load multiple small components onto the large measurement stage of LVC400 and measure the whole lot in one program, saving valuable time.

Easy to use M3 software

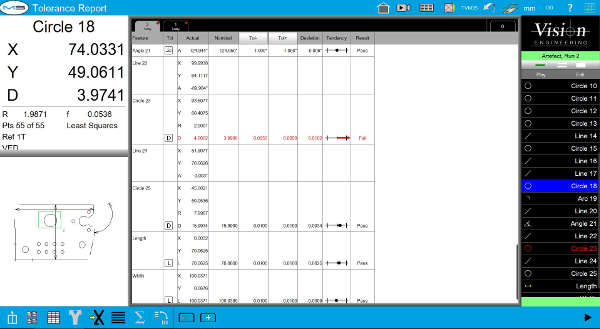

LVC400 is supplied with the highly intuitive and user friendly M3 software that offers advanced functionality and reporting capabilities:

- DXF import/export and DXF overlays

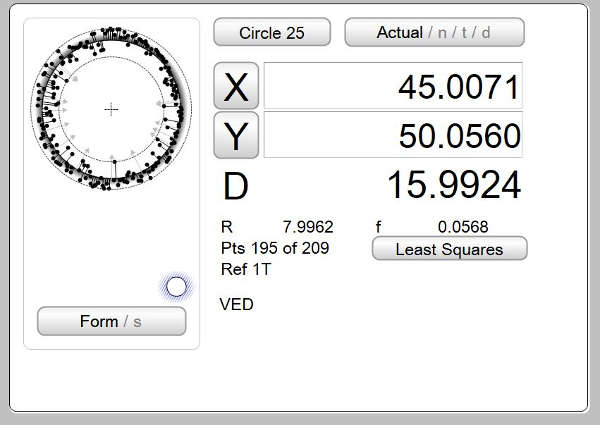

- Advanced edge detection

- Simple SPC

- Direct data transfer to Excel

- Formula results via Calculation feature

- Stitching and pallet programs

- Multi-feature finder tool

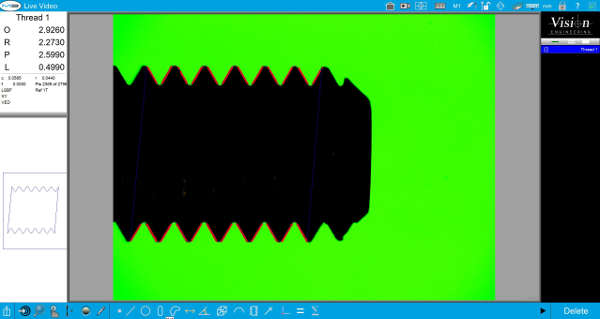

- Thread measurement option

LVC400 has the power and flexibility to meet the most demanding measurement requirements and suits industry applications including precision machining, casting, plastic moulding, electronics and medical device manufacturing.

- Measuring range 400mm x 300mm x 200mm

- 6-position motorised zoom lens

- 3D touch probe option