How does PZ-59 work?

Ordinary Pliers

Ordinary pliers jaws are lined with horizontal serrations. When you grasp and turn a screw head with ordinary pliers, the jaws slip and the screw remains stuck.

The tips of jaws can not reach the outer edge of screw head when the jaws are opened.

PZ-58

Specially-designed teeth generate gripping power.

The serrated jaws angled inward grab the rim of screw head, so no slippage.

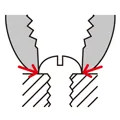

Why does PZ-59 have Inter-meshed Teeth?

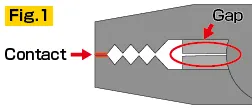

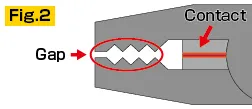

【Disadvantage of traditional pliers】

Should the top jaws of traditional pliers make contact with each other, then this results in a small gap between the rearmost cutting blades (Fig. 1). To avoid this, traditional pliers usually have a tiny gap between the top jaws to ensure the rearmost cutting blades fully meet (Fig. 2). Because of this, traditional pliers can not securely grip very thin materials such as shim plate etc

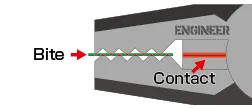

【Benefit of Inter-meshed teeth】

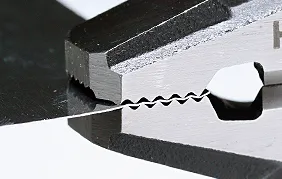

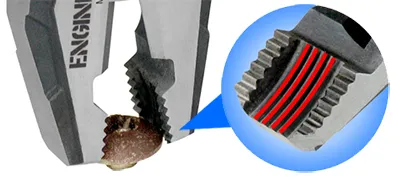

The side jaws of PZ-59 are specially designed to have ‘crests’ and ‘troughs’ that inter-mesh with each other.

So, when the rearmost cutting blades fully meet, the gripping jaws inter-mesh enough to hold extremely-thin plates very securely as well as thicker materials. Every peak of serrated teeth can bite into the material (as per the red markings on the right-hand figure). This is a major benefit over traditional pliers.

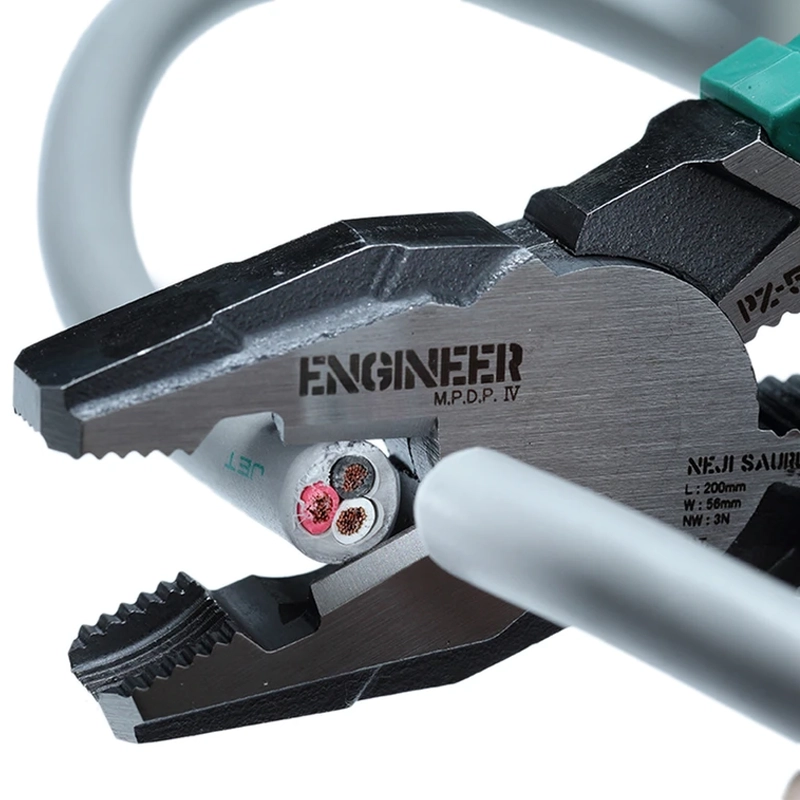

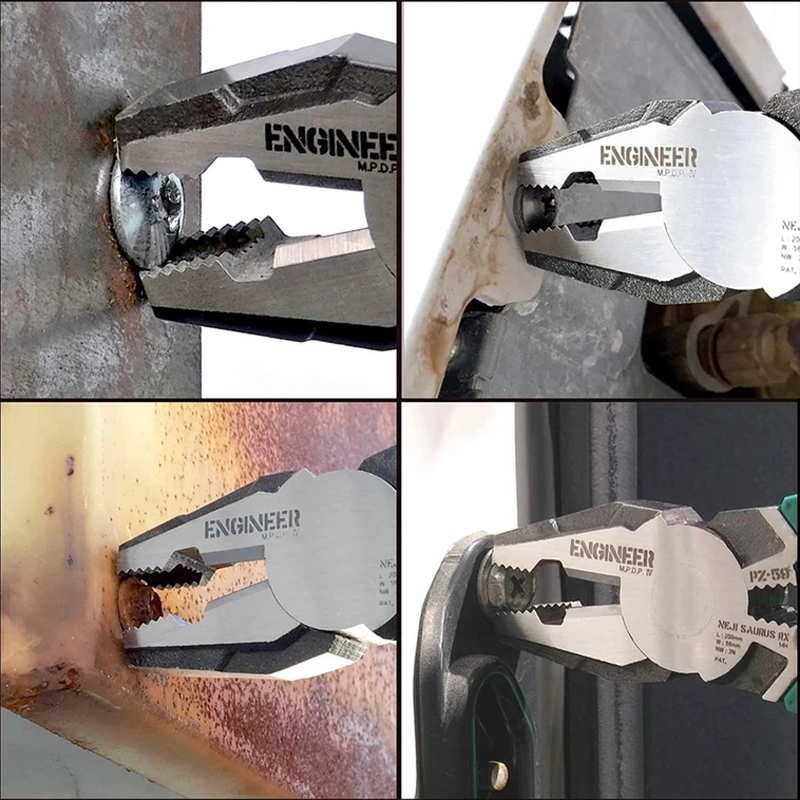

Applications

Stripped

Rusted

Torx

Dome Head

Screw Head Size

Round or Pan Head

Screw head: dia. 3 to 12mm

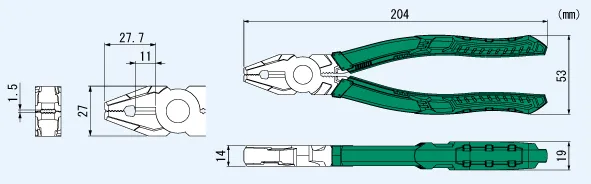

Heavy-duty T-shaped handles

Light weight (20% less in-house comparison)

Note

2- Be sure to apply this tool to a screw head, but not to screw thread.

Vertical Serrations to bite & grip a screw head

Unique jaws with serrations can grip a rusted or damaged head firmly without slipping.