It can be used economically when large quantities of milled PCBs have to be separated. Up to 15 PCBs arranged next to one another can be separated simultaneously. 310 mm is the maximum passage width. The distances and the number of circular blades are adapted to the PCB. Solid and precisely manufactured blade shafts ensure smooth PCB separation. The hardened and ground and titaniumcoated circular blades achieve a high running performance.

PCBs are inserted to the guide manually or are fed automatically by a loader resp. an external conveyor belt. When separated, the PCBs are deposited on the built-in conveyor belt. A SMEMA interface provided, installation in an assembly line is possible (for information see the operator’s manual). With the help of a base frame vertically adjustable, MAESTRO 5L can be adapted to any application. A possibility to connect an extraction and filter device is in preparation.

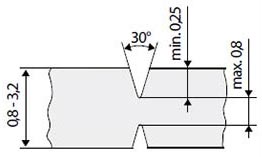

| Outside dimensions increased after separation: typically 0.2 mmThe milled groove may be interrupted by cutouts. |

|

| Technical data | Maestro 5L | |

|---|---|---|

| Separation method | Component side: Circular blade Solder side: Circular blade |

|

| Operation | motor-driven | |

| Separation speed | 100 – 220 mm/s to be set in ten steps | |

| PCB length light barrier activated light barrier deactivated |

100 – 570 mm up to 2,000 mm |

|

| PCB width | up to 310 mm | |

| Residual off-cut width | at least 3 mm | |

| Component height | Component side up to 30 mm Solder side up to 10 mm |

|

| Number of circular blades | up to 16 per blade shaft | |

| Programming | ||

| Display |

|

|

| Control buttons |

|

|

| Programming buttons |

|

|

| Monitoring |

|

|

| Interfaces |

|

|

| Power supply | 230/115 VAC, 50/60 Hz | |

| Temperature / humidity Operation Temperature / humidity Stock Temperature / humidity Transport |

+ 10 – 35°C / 10 – 85 % not condensing 0 – 60°C / 20 – 80 % not condensing – 25 – 60°C / 20 – 80 % not condensing |

|

| Width x Height x Depth | 440 x 750 – 1,000 x 1,100 mm | |

| Weight | 63 kg | |

| Approvals | CE, FCC Class A | |