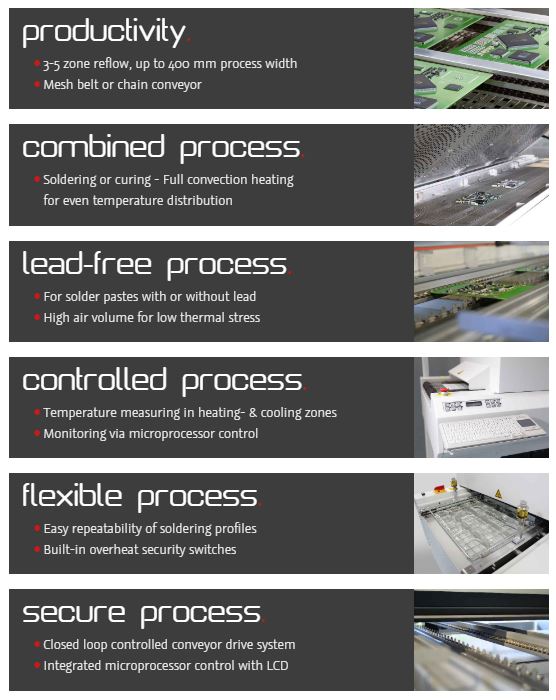

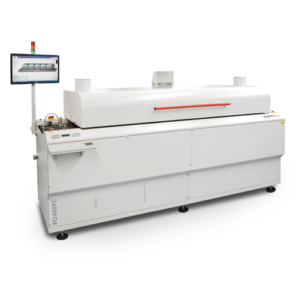

We introduce – The Lizard – Demands for a modern oven are not only in soldering and curing, but in particular in zone regulation, storing of profiles and the extra high air circulating volume for complex PCB. The RO-Ovens use full convection only to heat PCBs homogeniously. 400 mm process width, integrated microprocessor for profile control and storage, optional flying thermocouples, temperature recording directly on the board level guarantee a flawless repeatability of soldering profiles.

| RO-400FC | RO-300FC | ||

|---|---|---|---|

| Control | Board counter | optional with sensor or standard with SMEMA | optional with sensor or standard with SMEMA |

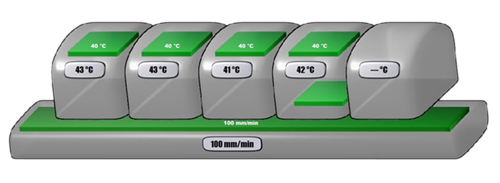

| Temperatur regulation | Adjustable from 20° to 290°C for each single zone | Adjustable from 20° to 290°C for each single zone | |

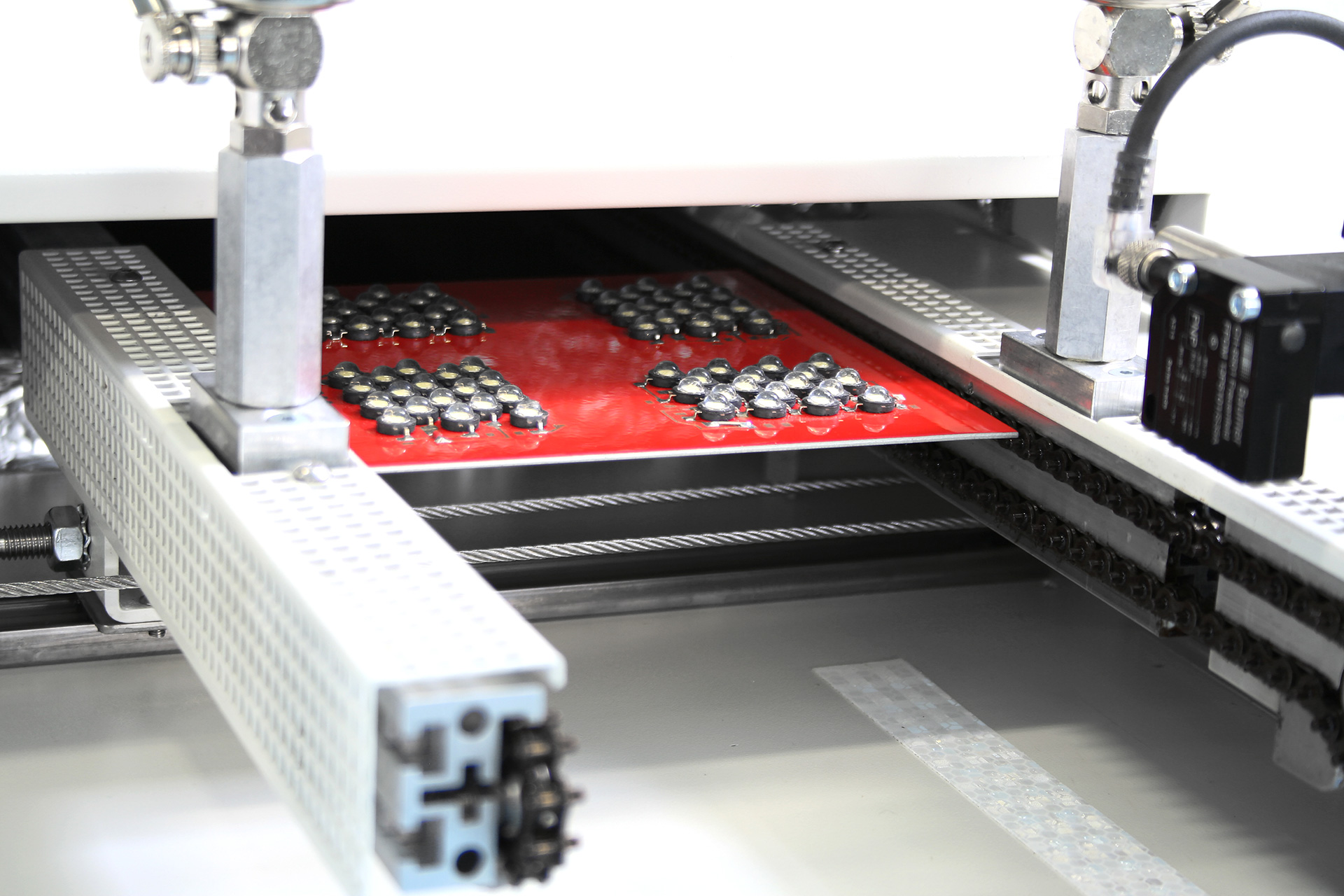

| PCB | PCB handling | Mesh belt or RO400FC-C Pin Chain | Mesh belt or RO300FC-C Pin Chain |

| Substrate width | 10 – 400 mm (0.39 – 15.8”), -C 60 – 400 mm (2.4-15.8”) | 10 – 300 mm (0.39 – 15.8”) | |

| Conveyor | Speed | 100 – 800 mm/min, Slow speed 10-200 mm/min | 100 – 800 mm/min, Slow speed 10-200 mm/min |

| Process | Heated length | 1‘620 mm (63.8”) | 1‘160 mm (45.7”) |

| Dimensions | Floor space | 2‘800 x 914mm (110.2 x 36“) | 2‘000 x 710 mm (78.8 x 28”) |

OPTIONAL EQUIPMENT

FOR OUR OVENS

Not just in SMT production, but in many other fields, our ovens ensure reliable processes.

A lens manufacturer for eyeglass lenses found problems in the constant heat supply of conventional ovens.

By using Essemtec ovens a crucial loss of material could be avoided