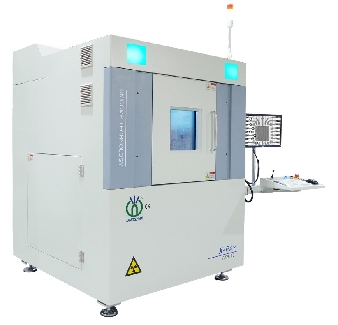

This includes BGA, CSP, QFN, flip chip, COB and various SMT components. is a powerful support tool for process development, process monitoring and refinement of rework operations. Backed by a powerful and easy-to-use software interface, x ray is able to meet the needs of small and large factories.

AX9100MAX X-RAY INSPECTION MACHINE

This X-ray is designed to provide high-resolution X-ray imaging for the electronics industry. This versatile system is effective for many applications in the PCB manufacturing process.

Download Datasheet

SKU

AX9100MAX

Category X-Ray Machines

Features and Benefits

● 90-130KV 7μm X-Ray tube.

● High speed & Millions pixels high resolution FPD.

● 1000X magnification, high-definition real-time image.

● One-button operation with 2.5D image display.

● Off-line programming function, navigation mode detection.

● 7 axis linkage, 70 degree tilt detection.

Applications

● SMT, BGA, CSP, Flip Chip, LED Detection.

● Semiconductor, Packaging components, Battery Industry.

● Electronic components, Auto parts, Photovoltaic Industry.

● Aluminum Die-casting, Moulding Plastic.

● Ceramics, Other Special Industries.

Technical Data

| Item | Definition | Specs |

| System Parameters | Size | 1350(L)x1250(W)x1700(H)mm |

| Weight | 1900kg | |

| Power | 220AC/50Hz | |

| Power Consumption | 1.6kW | |

| X-ray Tube | Type | Closed |

| Max.Voltage | 130kV | |

| Max.Power | 40W | |

| Spot Size | 7μm | |

| X-ray System | Intensifier | FPD |

| Monitor | 22 ‘’LCD | |

| System Magnification | 1600 X | |

| Detection Region | Max.Loading Size | Φ570mm |

| Max.Inspection Area | 450mm x 450mm | |

| X-ray Leakage | <1μSv/h | |