Fixture Mount Screwdrivers / PLUTO Series

PLUTO Screwdrivers for Automation | Torque range 0.5 − 50 Nm

PLUTO CA screwdrivers are designed for automated and fixtured applications. Whether you’re working with a robot or adapting your assembly line to Industry 4.0 standards, we have the right solution for automation in all its forms.

Long-lasting quality

LUTO® Screwdrivers feature an innovative coreless motor with low inertia and friction and absence of iron losses for extreme efficiency and extended life. Planetary gearboxes are made of high-quality composite materials for excellent accuracy and repeatability throughout the wide 0.5 – 50 Nm torque range.

Perfect for automatic machines

PLUTO CA are supplied in an aluminium body for a quick and easy integration with automatic machines and screwfeeding systems. PLUTO tools in CA/FN version are equipped with a flange mount and reciprocating spindle for high volume/high duty applications.

Robotic applications

Our PLUTO CA screwdrivers can be easily interfaced with robots. The EDU2AE screwdriver controller connects to robots to determine screw speed, torque and time out. The controller sends a signal to the robot when the screw reaches the specified torque.

Industry 4.0 ready

Simply connect the screwdriver controller to your PLC, robot or machine through the proper connectors to manage input/output signals such as start, stop, error and more. You can also get data reports of the full tightening procedure on advanced control units like EDU2AE/TOP/E and EDU2AE/TOP/TA.

Available Housings

ALUMINIUM BODY (PLUTO CA and PLUTO CA/N) – Specifically designed for automation. Easy to install on any machine or robot.

ALUMINIUM BODY WITH FLANGE MOUNT (PLUTO CA/FN and PLUTO CA/FN2) – Ideal for automated high volume/high duty applications. Flange and telescopic spindle available together or separately.

Aluminium housing PLUTO Screwdrivers

| Code | Model | Torque Nm | RPM min-max | Dimensions mm | Weight kg | Bit Drive |

| 130303 | PLUTO3CA | 0.5 – 3 | 370 – 1300 | 168 x 40 | 0.50 | Hex 1/4” |

| 133206 | PLUTO6CA | 0.85 – 6 | 200 – 850 | 168 x 40 | 0.50 | Hex 1/4” |

| 133211/N | PLUTO10CA/N | 1.5 – 10 | 110 – 600 | 168 x 40 | 0.50 | Hex 1/4” |

| 133216/N | PLUTO15CA/N | 2.0 – 15 | 60 – 320 | 168 x 40 | 0.50 | Hex 1/4” |

| 133221 | PLUTO20CA | 3.0 – 20 | 50 – 200 | 232 x 47 | 1.10 | Sq 3/8” |

| 133236 | PLUTO35CA | 3.0 – 35 | 40 – 140 | 247 x 57 | 1.50 | Sq 3/8” |

| 13325 | PLUTO50CA | 5.0 – 50 | 20 – 90 | 252 x 57 | 1.50 | Sq 1/2” |

Aluminium housing PLUTO Screwdrivers with flange mount

| Code | Model | Torque Nm | RPM min-max | Dimensions mm | Weight kg | Bit Drive |

| 130303/FN2 | PLUTO3CA/FN2 | 0.5 – 3 | 370 – 1300 | 268 x 40 | 0.70 | Sq 3/8” |

| 130303/FN2/1-4 | PLUTO3CA/FN2/1-4 | 0.5 – 3 | 370 – 1300 | 247 x 40 | 0.70 | Hex 1/4” |

| 133206/FN2 | PLUTO6CA/FN2 | 0.85 – 6 | 200 – 850 | 268 x 40 | 0.70 | Sq 3/8” |

| 133206/FN2/1-4 | PLUTO6CA/FN2/1-4 | 0.85 – 6 | 200 – 850 | 247 x 40 | 0.70 | Hex 1/4” |

| 133211/FN2 | PLUTO10CA/FN2 | 1.5 – 10 | 110 – 600 | 268 x 40 | 0.70 | Sq 3/8” |

| 133211/FN2/1-4 | PLUTO10CA/FN2/1-4 | 1.5 – 10 | 110 – 600 | 247 x 40 | 0.70 | Hex 1/4” |

| 133216/FN2 | PLUTO15CA/FN2 | 2.0 – 15 | 60 – 320 | 268 x 40 | 0.70 | Sq 3/8” |

| 133221/FN | PLUTO20CA/FN | 3.0 – 20 | 50 – 200 | 323 x 47 | 1.35 | Sq 3/8” |

| 133236/FN | PLUTO35CA/FN | 3.0 – 35 | 40 – 140 | 338 x 57 | 1.95 | Sq 3/8” |

| 133250/FN | PLUTO50CA/FN | 5.0 – 50 | 20 – 90 | 351 x 57 | 1.95 | Sq 1/2” |

Control units for PLUTO Screwdrivers

| Code | Model | Single Program | Torque Value in Nm | Serial Port | Multitorque (8P-sets) | PC.Software | Weight kg | Dimensions.mm | |

| 032000 | EDU2AE | • | – | – | – | – | 2.40 | 195 x 170 x 110 | |

| 032000/HPRO | EDU2AE/HPRO | • | • | • | – | – | 2.40 | 195 x 170 x 110 | |

| 032000/TOP | EDU2AE/TOP | – | • | • | • | – | 2.50 | 190 x 205 x 120 | |

| 032000/TOP/E | EDU2AE/TOP/E | – | • | • | • | • | 2.50 | 190 x 205 x 120 | |

Fixture Mount Screwdrivers / Torque & Angle Series

Torque & Angle Screwdrivers for Automation | Torque range 0.02 − 50 Nm

Automation requires accurate torque controlling techniques. TA automated systems feature advanced monitoring strategies such as torque and rotation angle of the screw, for precise torque and angle control on all automated operations.

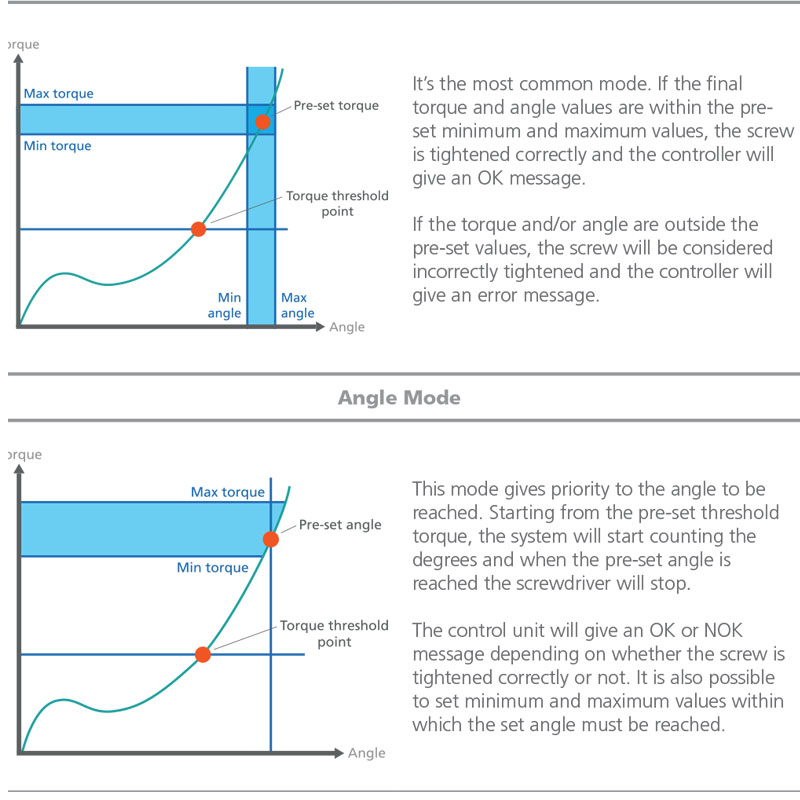

The Torque/Angle Control

The main parameters to be controlled are the tightening torque and the rotation angle of the screw, either with torque or angle priority. The screwdriver stops automatically when the pre-set angle and torque value have been reached and an indication of OK cycle (green led turned on) is given, otherwise a red led turns on if the tightened screw doesn’t match the pre-set parameters. The final torque and angle values are also displayed.

Easy interface

TA Screwdrivers work in combination with EDU2AE/TOP/TA control units, which allow to set, change and save all parameters via PC, USB key and a wide range of I/O connections for an easy interface with your PLC, robot or machine.

Plenty of options

PLUTO, MITO and NATO automated torque & angle screwdrivers cover a wide torque range of 0.1-50 Nm: choose the tool that best suits your application and set the desired working cycle through TOP/TA control units. You can set 8 independent programs either directly on control unit or remotely. TA automated screwdrivers give you total control over automated applications.

Industry 4.0

Interconnection, automatic control and continuous monitoring are fundamental aspects of Industry 4.0. Through EDU2AE/TOP/TA control units you can easily manage input and output signals such as start, stop, error and more. You can also get data reports of the full tightening procedure on PC, USB key or serial connection.

EDU2AE/TOP/TA Torque and Angle Functionalities

Aluminium housing TA Screwdrivers

| Code | Model | Torque Nm | RPM min-max | Dimensions mm | Weight kg | Bit Drive |

| 163015/TA | NATO15CA/TA | 0.02 – 0.27 | 100 – 700 | 150 x 25 | 0.18 | Half moon 4 mm |

| 163050/TA | NATO50CA/TA | 0.05 – 0.5 | 50 – 700 | 150 x 25 | 0.18 | Hex 1/4” |

| 170016/TA | MITO15CA/TA | 0.35 – 1.5 | 450 – 850 | 193 x 32 | 0.36 | Hex 1/4” |

| 130303/TA | PLUTO3CA/TA | 0.5 – 3 | 370 – 1300 | 168 x 40 | 0.50 | Hex 1/4” |

| 133206/TA | PLUTO6CA/TA | 0.85 – 6 | 200 – 850 | 168 x 40 | 0.50 | Hex 1/4” |

| 133211/TA | PLUTO10CA/TA | 1.5 – 10 | 110 – 600 | 168 x 40 | 0.50 | Hex 1/4” |

| 133216/TA | PLUTO15CA/TA | 2.0 – 15 | 60 – 320 | 168 x 40 | 0.50 | Hex 1/4” |

| 133221/TA | PLUTO20CA/TA | 3.0 – 20 | 50 – 200 | 232 x 47 | 1.10 | Sq 3/8” |

| 133236/TA | PLUTO35CA/TA | 3.0 – 35 | 40 – 140 | 247 x 57 | 1.50 | Sq 3/8” |

| 133250/TA | PLUTO50CA/TA | 5.0 – 50 | 20 – 90 | 252 x 57 | 1.50 | Sq 1/2” |

Aluminium housing TA Screwdrivers with flange mount

| Code | Model | Torque Nm | RPM min-max | Dimensions mm | Weight kg | Bit Drive |

| 170016/FN/TA | MITO15CA/FN/TA | 0.35 – 1.5 | 450 – 850 | 271 x 32 | 0.40 | Hex 1/4” |

| 130303/FN2/TA | PLUTO3CA/FN2/TA | 0.5 – 3 | 370 – 1300 | 268 x 40 | 0.70 | Sq 3/8” |

| 130303/FN2/TA/1-4 | PLUTO3CA/FN2/TA/1-4 | 0.5 – 3 | 370 – 1300 | 247 x 40 | 0.70 | Hex 1/4” |

| 133206/FN2/TA | PLUTO6CA/FN2/TA | 0.85 – 6 | 200 – 850 | 268 x 40 | 0.70 | Sq 3/8” |

| 133206/FN2/TA/1-4 | PLUTO6CA/FN2/TA/1-4 | 0.85 – 6 | 200 – 850 | 247 x 40 | 0.70 | Hex 1/4” |

| 133211/FN2/TA | PLUTO10CA/FN2/TA | 1.5 – 10 | 110 – 600 | 268 x 40 | 0.70 | Sq 3/8” |

| 133211/FN2/TA/1-4 | PLUTO10CA/FN2/TA/1-4 | 1.5 – 10 | 110 – 600 | 247 x 40 | 0.70 | Hex 1/4” |

| 133216/FN2/TA | PLUTO15CA/FN2/TA | 2.0 – 15 | 60 – 320 | 268 x 40 | 0.70 | Sq 3/8” |

| 133221/FN/TA | PLUTO20CA/FN/TA | 3.0 – 20 | 50 – 200 | 323 x 47 | 1.35 | Sq 3/8” |

| 133236/FN/TA | PLUTO35CA/FN/TA | 3.0 – 35 | 40 – 140 | 338 x 57 | 1.95 | Sq 3/8” |

| 133250/FN/TA | PLUTO50CA/FN/TA | 5.0 – 50 | 20 – 90 | 351 x 57 | 1.95 | Sq 1/2” |

Control units for TA Screwdrivers

| Code | Model | NATO TA Series | PLUTO,MITO TA Series | Serial Port | Multitorque (8 P-sets) | Computer Interface | Torque & Angle | Weight kg | Dimensions mm |

| 031000/TOP/NT/TA | EDU2AE/TOP/NT/TA | • | – | • | • | • | • | 2.00 | 190 x 205 x 120 |

| 032000/TOP/TA | EDU2AE/TOP/TA | – | • | • | • | • | • | 2.50 | 190 x 205 x 120 |

Fixture Mount Clutch Screwdrivers / KBL Series

KBL Screwdrivers for Automation | Torque range 0.04 − 4 Nma

KBL CA Screwdrivers combine state-of-the-art brushless motors with an aluminium housing for quick and easy installation on robots and automatic machines.

Designed for automation

KBL CA tools are supplied in an aluminium body for a quick and easy integration with automatic machines and screw feeding systems. KBL tools in CA/FN version are equipped with a flange mount and reciprocating spindle for high-intensity applications.

Easy to install and operate

Each KBL CA screwdriver works in combination with an EDU1BL/SG control unit. Its electronic control circuit cuts the power supply to the screwdriver motor in response to the clutch action, as soon as the pre-set torque has been reached. KBL’s torque clutch only needs to be set once and guarantees accurate repeatability on any kind of joint.

Industry 4.0 with KBL

Transitioning to Industry 4.0 is easy with KBL CA screwdrivers. They can be easily connected to robots or automatic machines through their EDU 1BL/SG controller’s proper connectors to manage input/output signals such as start, stop, error and more.

No maintenance required

Automation requires tools capable of keeping high quality standards, even on heavy-duty applications. KBL Screwdrivers combine Swiss brushless motors with magnetic clutch switches for a real maintenance -free solution. The absence of maintenance operations guarantees high productive continuity

For clean-room environments

KBL screwdrivers are perfect for automated applications requiring cleanroom standards. No brushes means zero emissions of carbon dust or other pollutants into the working environment, which guarantees high-quality assembly on any joint.

Available Housings

ALUMINIUM BODY (KBL CA) – Specifically designed for automation. Easy to install on any machine or robot.

ALUMINIUM BODY WITH FLANGE MOUNT (KBL CA/FN) – Ideal for automated high volume/high duty applications. Flange and telescopic spindle available together or separately.

Robotic application

SCAN TO WATCH

Aluminium housing KBL Screwdrivers

| Code | Mode | Torque Nm | RPM min-max | Dimensions mm | Weight kg | Bit Drive |

| 190004/CA | KBL04FR/CA | 0.04 – 0.4 | 700 – 1150 | 257 x 40 | 0.60 | Hex 1/4″ |

| 190015/CA | KBL15FR/CA | 0.4 – 1.5 | 700 – 1150 | 257 x 40 | 0.60 | Hex 1/4″ |

| 190030/CA | KBL30FR/CA | 0.7 – 3 | 700 – 1150 | 264 x 40 | 0.75 | Hex 1/4″ |

| 190040/CA | KBL40FR/CA | 0.9 – 4 | 400 – 700 | 264 x 40 | 0.75 | Hex 1/4″ |

Aluminium housing KBL Screwdrivers with flange mount

| Code | Model | Torque Nm | RPM min-max | Dimensions mm | Weight kg | Bit Drive |

| 190004/CA/FN | KBL04FR/CA/FN | 0.04 – 0.4 | 700 – 1150 | 330 x 40 | 0.65 | Hex 1/4″ |

| 190015/CA/FN | KBL15FR/CA/FN | 0.4 – 1.5 | 700 – 1150 | 330 x 40 | 0.65 | Hex 1/4″ |

| 190030/CA/FN | KBL30FR/CA/FN | 0.7 – 3 | 700 – 1150 | 338 x 40 | 0.80 | Hex 1/4″ |

| 190040/CA/FN | KBL40FR/CA/FN | 0.9 – 4 | 400 – 700 | 338 x 40 | 0.80 | Hex 1/4″ |

Control unit for KBL CA Screwdrivers

| Code | Model | Ramp Option | Settable Speed | I/O Signals | Serial Print | Screw Count | Min-Max Run Time | Weight kg | Dimensions mm |

| 003000/SG | EDU1BL/SG | • | • | • | with ACE | with ACE | with ACE | 0.60 | 138 x 118 x 67 |