Torque Tester / K and mini K/S Series

K and Mini K/S Series Torque Testers | Torque range 0.05 − 50 Nm

Controlling torque is vital for companies to ensure their product’s quality. Fasteners that are insufficiently torqued can vibrate loose and excessive torque can strip threaded fasteners. Using a quality torque tester has become increasingly important for most companies to ensure that proper torque is being applied.

Mini Ke/S Series with External Transducer

The Mini Ke/S system consists of a torque readout and an external rotary transducer. By connecting a rotary torque transducer between an electric or pneumatic tool and an assembly application, you can monitor the real torque being applied from the tool to fastener or bolt.

It is possible to connect different transducers to the same torque reader by setting the proper Correction Factor (FATC). A Mini Ke/S is the ideal torque-auditing tool for testing the actual torque being applied on the assembly application.

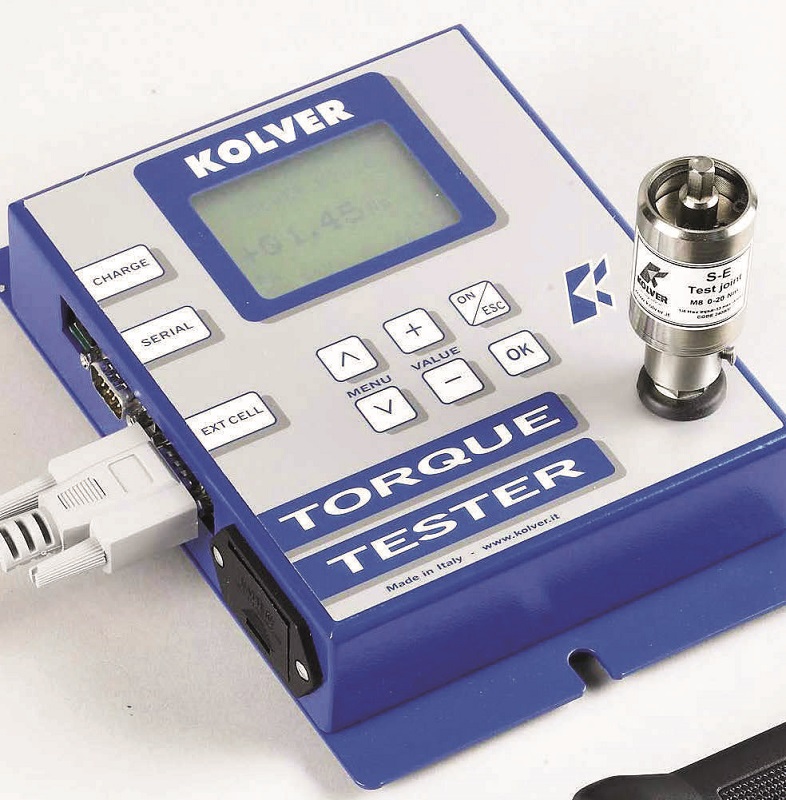

Mini K/S Series – Portable Torque Testers

MINI K/S Torque Testers feature a built-in transducer. These easy-to-use torque testers are ideal for checking all power tools up to 20 Nm. The small size and portability of MINI K/S make them ideal for checking torque tools on the production floor regularly to ensure the tools are always calibrated.

- Three units of torque measurement available; Nm, Kg.cm, in/lbs.

- Manual and auto reset functions to clear displayed values.

- Battery powered (9V) and AC adapter. 9V battery provides 30 hours of continuous operation.

- Automatic shut down to extend battery life.

- mini USB port for printing torque values, date and hour

- Torque Tester includes a washer-based joint simulator (miniK5/S and miniK20/S) or built in joint simulator (miniK1/S), instructions manual, certificate of calibration and a case.

K Series – Advanced Torque Testers

The K Series Torque Testers feature a built-in transducer and can also be connected to an external transducer. They collect, store and eventually download torque measures for a complete analysis of the tool and/or the joint.

Main features include:

- 500 readings memory.

- Selection among Nm, Ncm, Kg.cm, in/lbs.

- RS232C output (cable not included).

- Indication < = > of the preset values

- Output signal at preset reached value.

- Clockwise and counter-clockwise measurements.

- 3 models of operation: Peak +, Peak -, Track.

- Manual or automatic reset.

- 9 V rechargeable battery provides 4 hours of continuous operation. Automatic switch off to reduce battery consumption.

Supplied in a plastic carrying case, with one rechargeable battery, 1 joint simulator (semielastic), instructions manual and certificate of calibration.

Model K Torque Testers

| Code | Model | Torque range Nm | Dimensions mm | Weight kg | Joint Simulator | External Transducer | Connecting Port |

| 020402 | K1 | 0.05 – 1 | 172 x 142 x 41 | 1.0 | Semi-Elastic M6 | – | RS232C |

| 020403 | K5 | 0.3 – 5 | 172 x 142 x 41 | 1.0 | Semi-Elastic M6 | KTE5 (optional) | RS232C |

| 020404

Optional External Trans |

K20 ducers | 0.5 – 20 | 172 x 142 x 41 | 1.0 | Semi-Elastic M8 | KTE25 (optional) | RS232C |

| 022405 | KTE5 | 0.5 – 5 | 25 x 92 | 0.3 | External Transducer for K5 | ||

| 022425 | KTE25 | 2 – 25 | 25 x 92 | 0.3 | External Transducer for K20 |

Model Mini K/S Torque Testers

| Code | Model | Torque range Nm | Dimensions mm | Weight kg | Joint Simulator | External Transducer | Connecting Port |

| 021402/S | Mini K1/S | 0.05 – 1 | 150 x 70 x 45 | 0.80 | Internal Simulator | – | mini USB |

| 021403/S | Mini K5/S | 0.3 – 5 | 150 x 70 x 45 | 0.80 | Semi-Elastic M6 | – | mini USB |

| 021404/S | Mini K20/S | 0.5 – 20 | 150 x 70 x 45 | 0.80 | Semi-Elastic M8 | – | mini USB |

| 021405/5/S | Mini Ke5/S | 0.5 – 5 | 150 x 70 x 45 | 0.50 | – | KTE5 (included) | mini USB |

| 021405/25/S | Mini Ke25/S | 2 – 25 | 150 x 70 x 45 | 0.50 | – | KTE25 (included) | mini USB |

| 021405/50/S | Mini Ke50/S | 5 – 50 | 150 x 70 x 45 | 0.50 | – | KTE50 (included) | mini USB |

Torque Analyzer Software

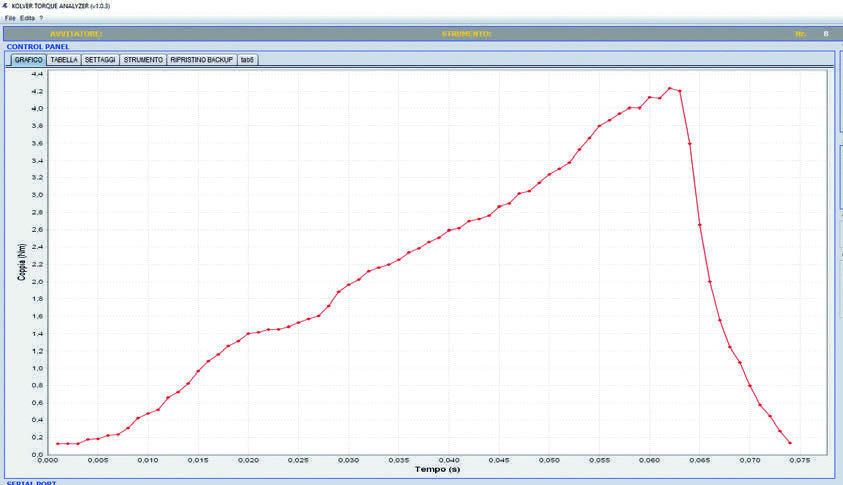

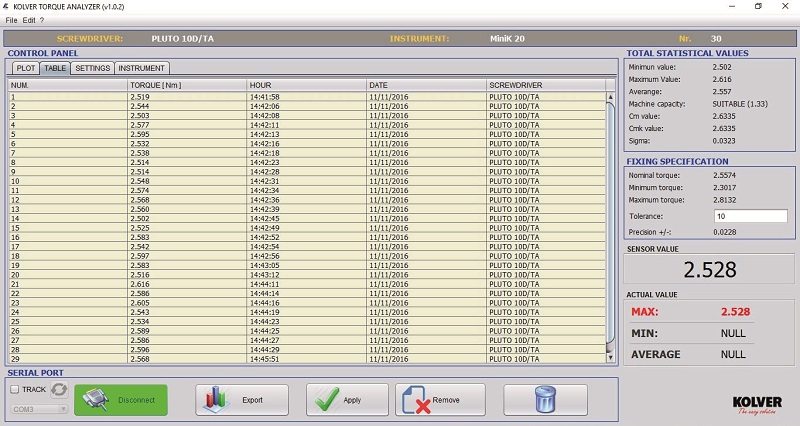

The new Kolver Torque Analyzer software for Mini K/S and Mini Ke/S Torque Testers features real-time tracking of each measurement and calculation of CM and CMK.

A Real-time chart for each torque measurement is displayed on your PC screen (when “track mode” on the tester is enabled). The chart will show the trend of the single screwing operation or, in case of multiple screwing operations it will show the results according to the settings on the torque tester and software (for example if you’re keeping track of multiple operations at max torque, the chart will show the trend of these max torques). You can also export an Excel file (max 30 measurements) with corresponding CM-CMK values: this is useful for testing the torque accuracy of the screwdriver.