PBT COMPACLEAN

PCB WASHING MACHINE

APPLICATION

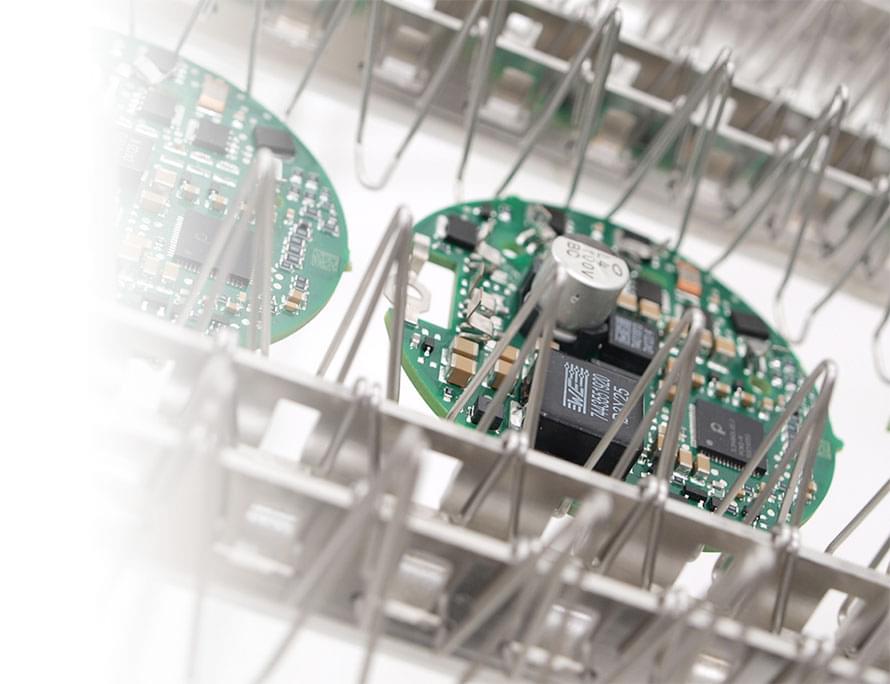

- De fluxing, removing activators and resin residues

- Cleaning contamination from handling and board manufacturing

- Cleaning second side misprints on complex assemblies

- Cleaning before conformal coating

- Cleaning of soldering pallets

- Fine degreasing of mechanical parts

CLEANING WITH CompaCLEAN

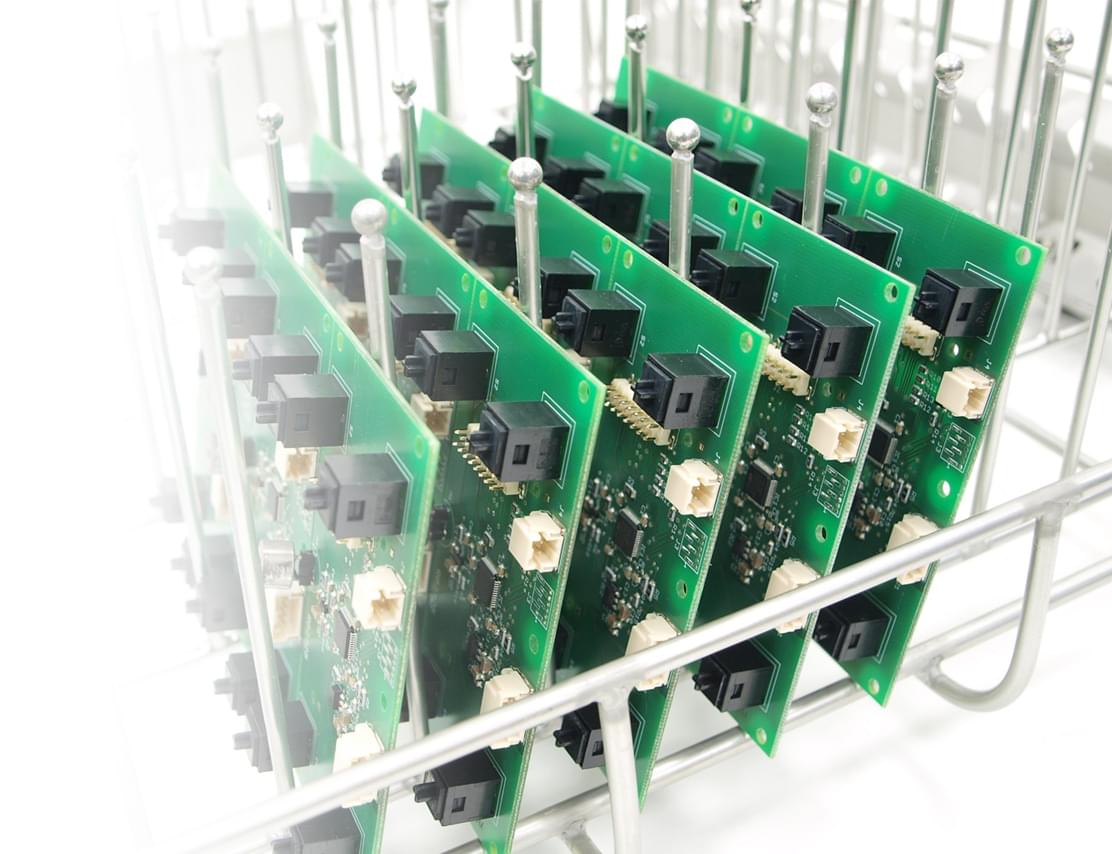

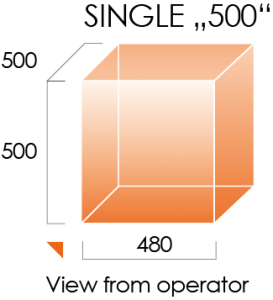

- SINGLE or DOUBLE capacity racks

- High volume batch size

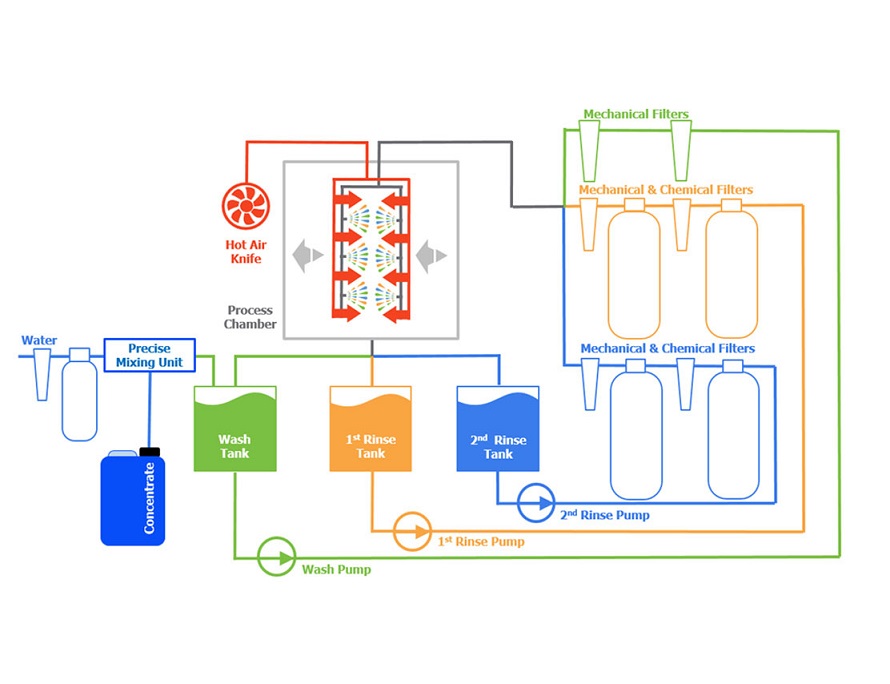

- Closed loop zero drain system

- Uniform spray coverage with high stroke oscillating rack

- Fixed nozzle system

- Powerful hot air dryer

- Cascade filtration

- Compatible with wide range of chemistry

- Small footprint

- 100% closed loop filtration

- Double rinse option

- Glass door panel for visual control

- Wide range of standard and customized PCBA fixtures

- Up to 3 fully separated liquid loops

- Outstanding options of water utilization

- Touchscreen interface with Windows OS

- Simple programming

- Complete data logging and optional bar code traceability

- Week program with automatic start

- Multi language selection

- AAD Automatic adaptive dosing of cleaning agent

- Concentration sensor ZESTRON® EYE or KYZEN ANALYST™

USABLE SPACE OF CHAMBER

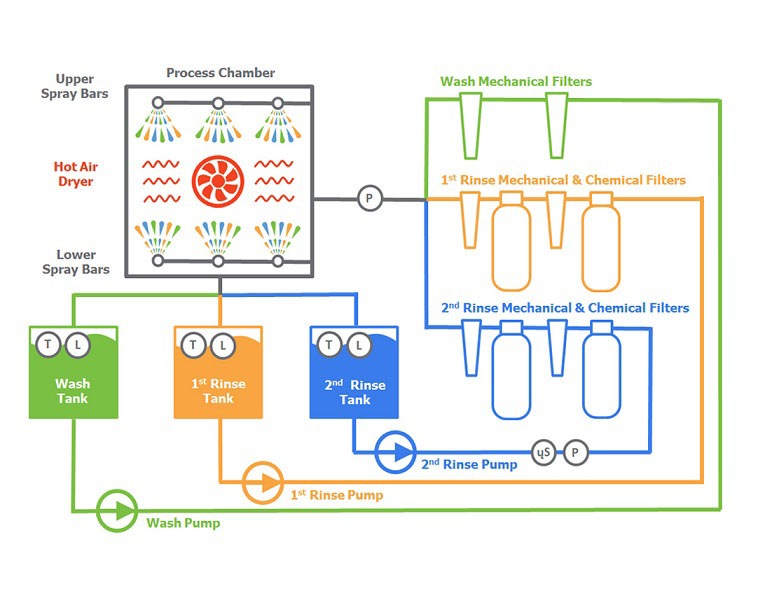

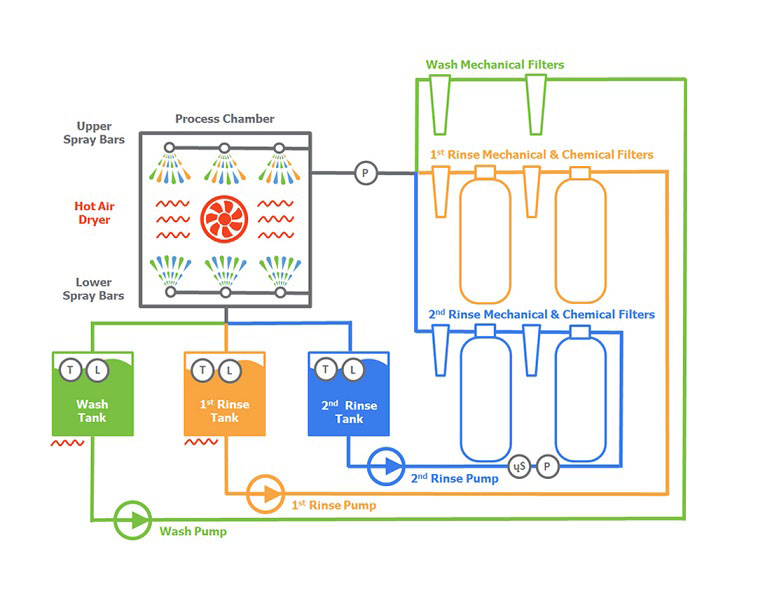

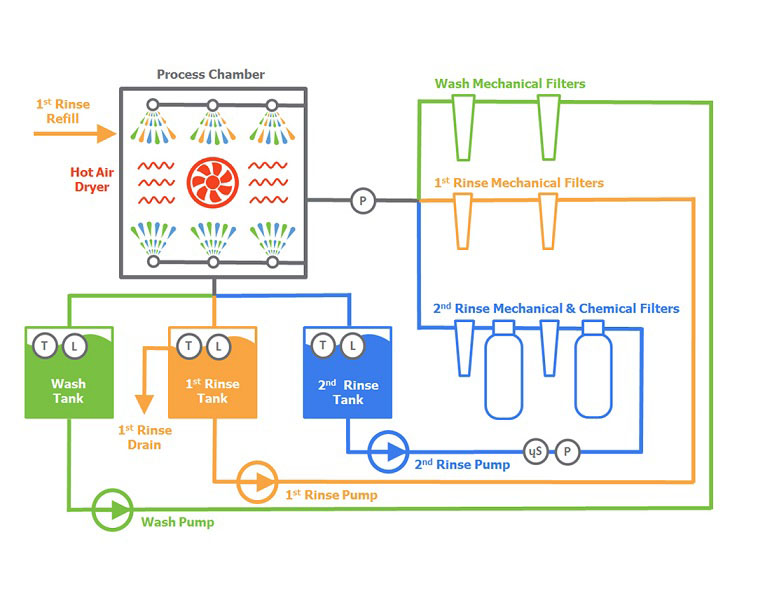

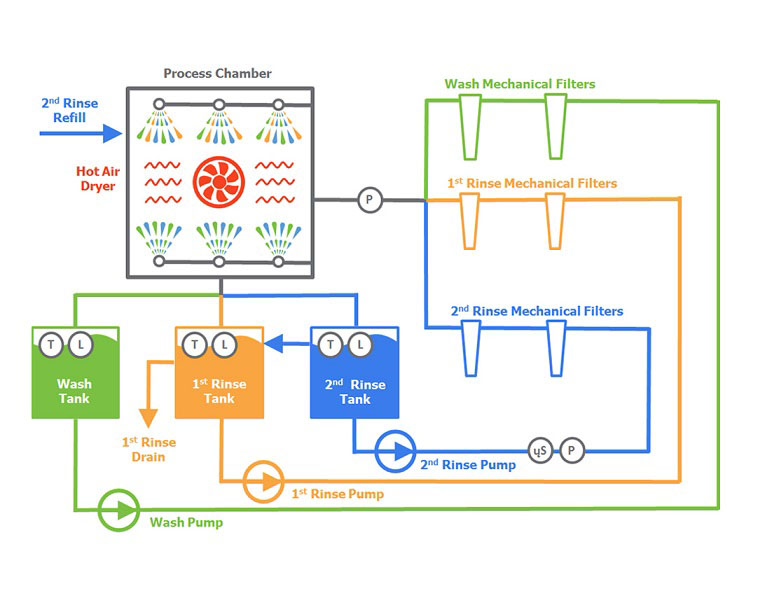

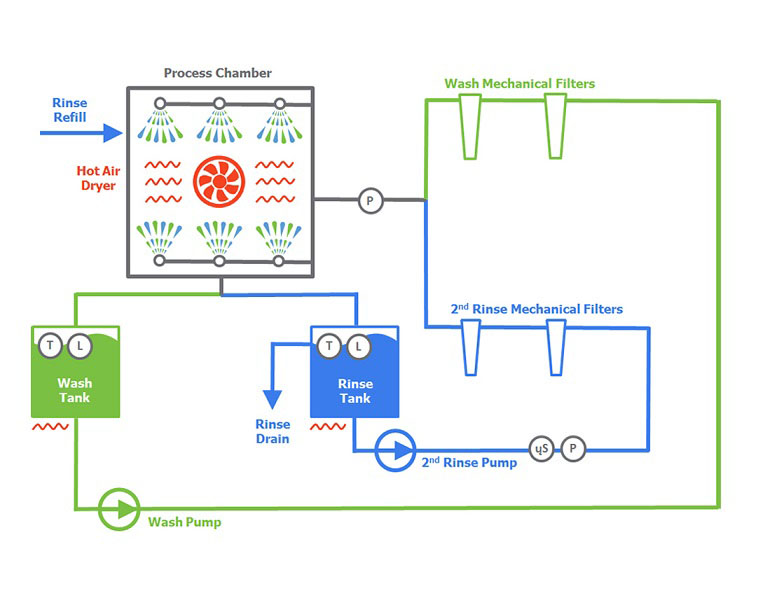

Filtration

- Developed to match modern cleaning agents

- Wash loop is closed and fully filtrated process

- Filtration extends the bath life to lower the process costs

- Various efficient ways of processing contaminated rinse loop water

- Rinse loops are flexible by design to meet various process and environmental requirements

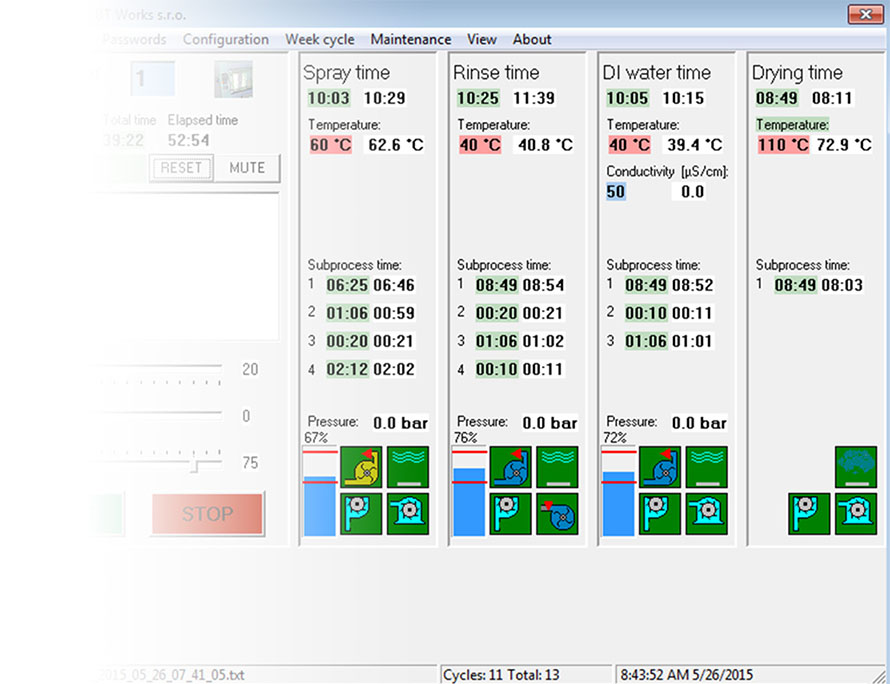

INTUITIVE TOUCHSCREEN INTERFACE

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters (time, temperature, pressure, conductivity-resistence, concentration etc.)

- Process steps may contain up to 5 substeps for perfect setup

- Indication of real level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Process messages, warnings and errors are clearly displayed

- All parameters and messages are saved on a simple log

- All process parameters can be easily viewed in graphs

- OS available in several different languages

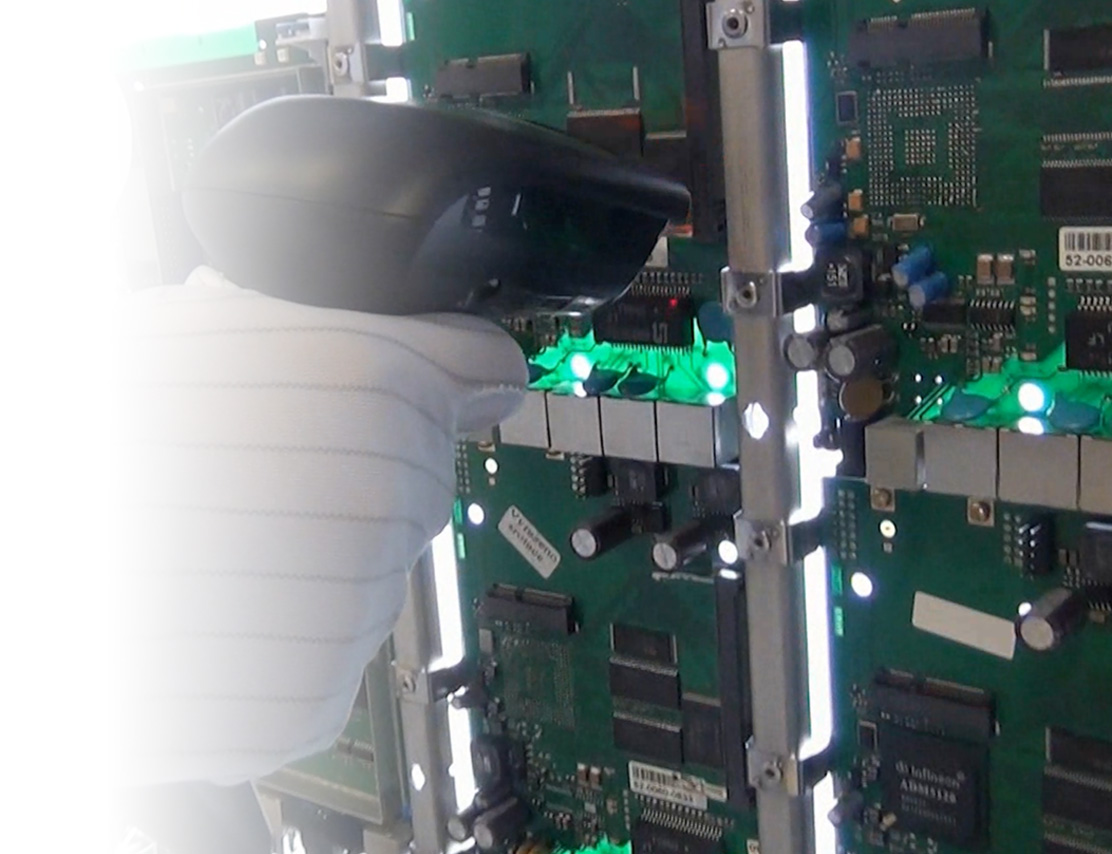

BAR CODE TRACEABILITY

- Barcode reader for product identification

- Automatic selection of cleaning program through barcode

- Complete archiving of barcodes with process parameters

- Traceability file created after each process with all set and real process data and messages, subsequently can be used in Manufacturing Execution System (MES)

CONCENTRATION MONITORING ZESTRON® EYE

- Automated digital concentration monitoring system ZESTRON® EYE enables precise measurement and control in real time

- Proper concentration of chemicals in wash loop necessary for stable and reliable cleaning process

- Data from ZESTRON® EYE are fully integrated in the machine software

- Designed for ZESTRON cleaning agents

- Process parameters can be set and viewed on the unit touchscreen

CONCENTRATION MONITORING KYZEN ANALYST™

- Real-time automatic concentration monitoring and reporting with KYZEN ANALYST™

- Stable and reliable cleaning process strongly depends on proper concentration of chemicals in wash loop

- Advanced data analytics system designed for all chemistries

- Data from KYZEN ANALYST™ are fully integrated in the machine software

- Process parameters can be set and viewed on the unit touchscreen