HyperCLEAN III

PCB Cleaning

Handling

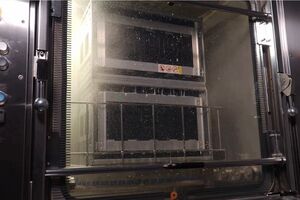

Handling the parts to be cleaned is simple and safe. The PCBAs can be loaded onto another cart while the machine cleans the first batch. This eliminates the need for the operator to lift and carry frames or baskets between the reloading point and the machine.

HyperCLEAN III

A pushcart is used to load and unload the batch into and out of the chamber.

Cleaning Technology

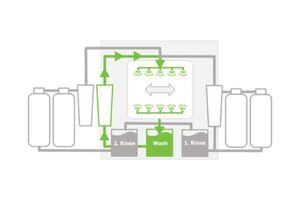

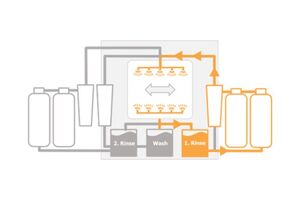

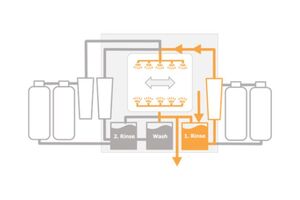

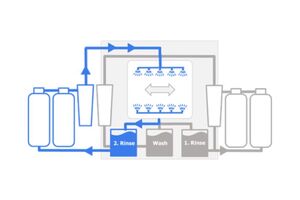

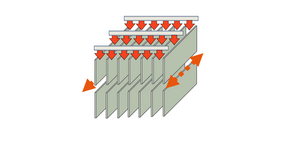

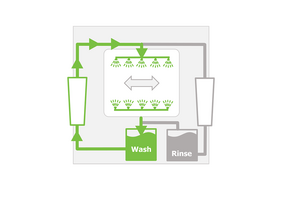

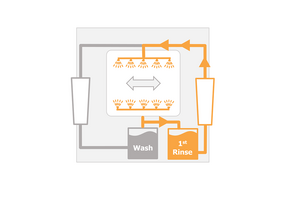

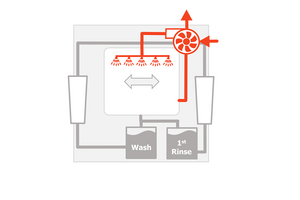

Quality cleaning requires perfect filtration and minimal cross-contamination. Each PBT cleaning machine uses a separate closed loop pump and filtration system for each individual process step.

Wash

Chemical Stop

1. Rinse

2. Rinse

Drying

Capacity

The HyperCLEAN has the largest chamber of any PBT machine and therefore is ideal for standard batch cleaning.

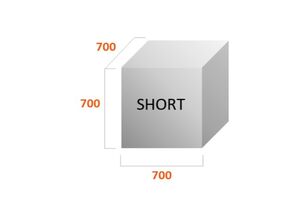

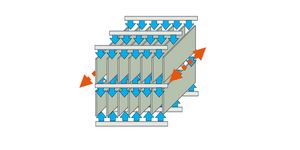

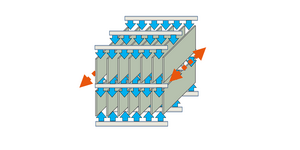

COMBO II Short

System uses double row baskets for pcb batch cleaning. The top, middle and bottom spray nozzles cover the entire surface of the chamber.

Short is a version of pushcart that offers oscillation of the basket for better cleaning results.

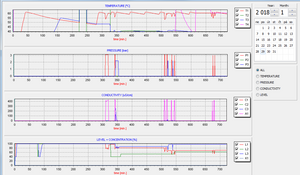

Process Control

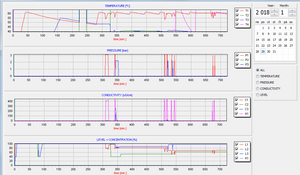

Cleaning process is sensitive to many variables.

High Performance Cleaning

It is essential to monitor all process parameters such as temperature, pressure/flow, concentration, conductivity and time.

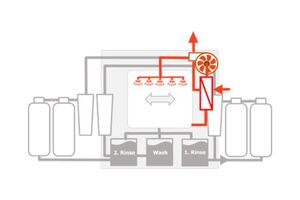

A perfect PCBA cleaning result requires a short but powerful spray technology and a fast but thorough drying process.

Uniform Spray

Hot Air Dry

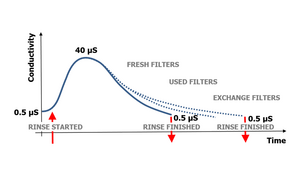

Adaptive Rinse Control

Liquid p-Q Monitoring

Wash concentration control

Water-based cleaners are mixtures of organic concentrate and deionised water. The optimum chemistry and its concentration is selected using the PBT Glass Test Board and confirmed by testing actual PCBA samples. The PBT machines then have several options to automatically monitor and/or control the concentration of the washing liquid in real time.

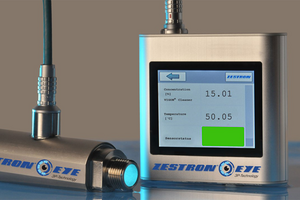

Zestron EYE

Monitors and analyzes washing liguid concentration of most cleaning agent brands in real-time. Calibrated for many Kyzen products as well as others. The measuring system is fully integrated into the control software.

Total solution for wash loop. Complete concentration and level control of the wash bath. Utilizes ZESTRON® EYE or KYZEN ANALYST™ measuring system and PBT dosing-mixing unit.

Programming and Data Capture

Perfect cleaning result requires detailed programing, quick visual and parametric evaluation of the entire process.

Intuitive Programming

Visual check

Traceability

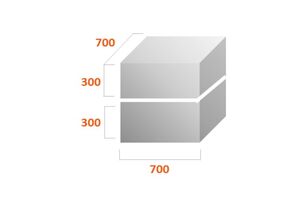

Usable Space Double Short

COMBO baskets

HyperCLEAN II

Maintenance Cleaning

Operator loads pushcart manually into the chamber. Optimal cost-effective solution for the typical SMT productions.

Cleaning Technology

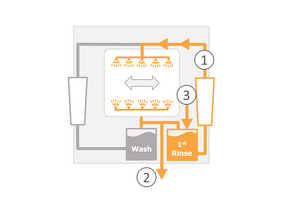

Quality cleaning requires perfect filtration and minimal cross-contamination. Each PBT cleaning machine uses a separate closed loop pump and filtration system for each individual process step.

Wash

Chemical Stop

First Rinse

using automatic water level and quality control.

Drying

Capacity

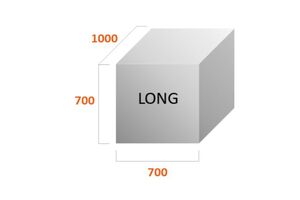

The HyperCLEAN has the largest chamber of any PBT machine and therefore is ideal for standard batch cleaning. Thanks to the quick-change clamping and nozzle system, the HyperCLEAN can be easily adapted to clean parts of any size and shape.

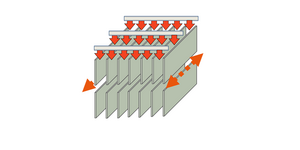

COMBO I Short

Short pushcart configuration for heavy contaminated parts with oscillation of the basket ensures better cleaning results.

For high volume cleaning of large size Solder Pallets, SMT Oven filters and other mechanical parts.

COMBO I Long

Long pushcart configuration for regular cleaning without oscillation.

Longer pushcart accommodates more pallets, magazines and other mechanical parts than Short.

Process Control

Cleaning process is sensitive to many variables.

High Performance Cleaning

Perfect result of PCBA cleaning requires short but powerful spray technology and rapid but thorough drying.

Uniform Spray

Hot Air Dry

Liquid p-Q Monitoring

Programming and Data Capture

Perfect cleaning result requires detailed programing, quick visual and parametric evaluation of the entire process.

Intuitive Programming

Illuminated Chamber

Process Parameters Traceability

Clamping

Requires usage of basic cart.

Usable Space Short