PBT SUPERSWASH

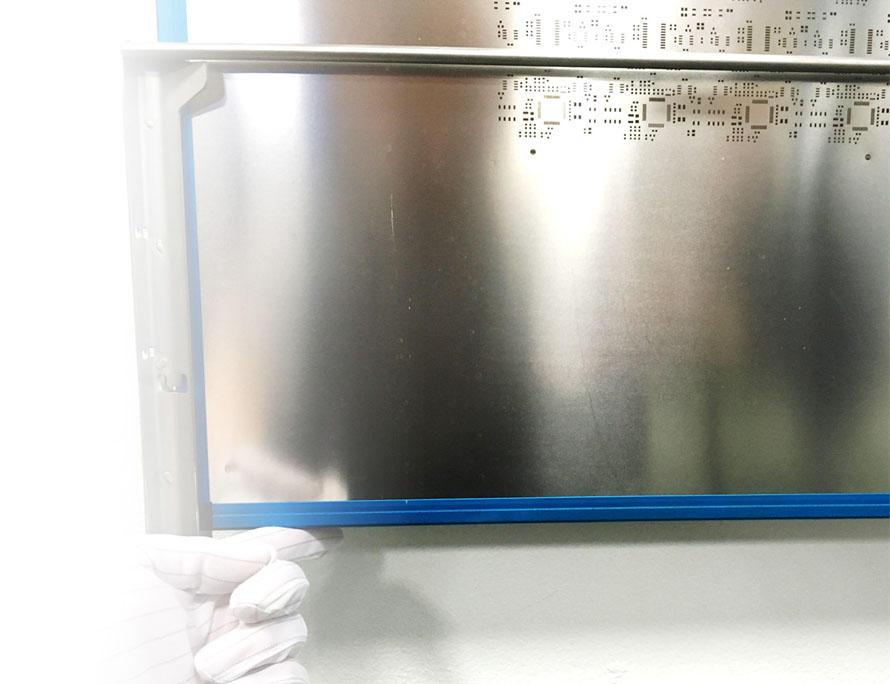

PCB/STENCIL WASHING MACHINE

- Defluxing, removing activators and resin residues

- Cleaning contamination from handling and board manufacturing

- Cleaning highly populated electronic assemblies with low standoff components such as BGA, CSP, LGA, MELF etc.

- Cleaning of power electronics

- Cleaning electronic assemblies requiring extra short process time

- Cleaning second side misprints on complex assemblies

- Cleaning before conformal coating

- Cleaning before wire bonding

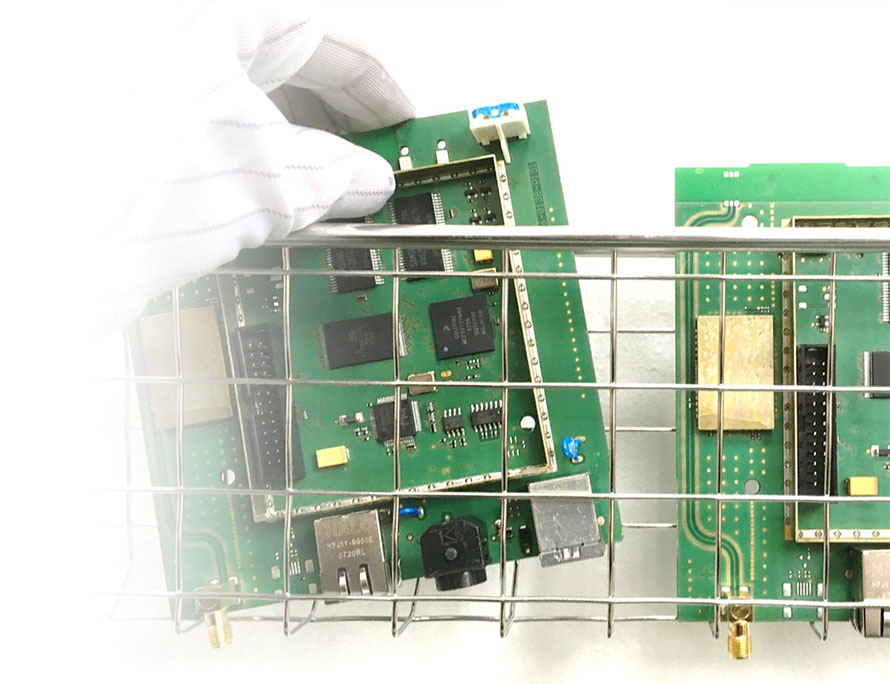

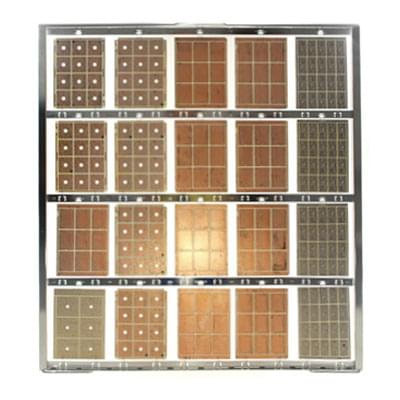

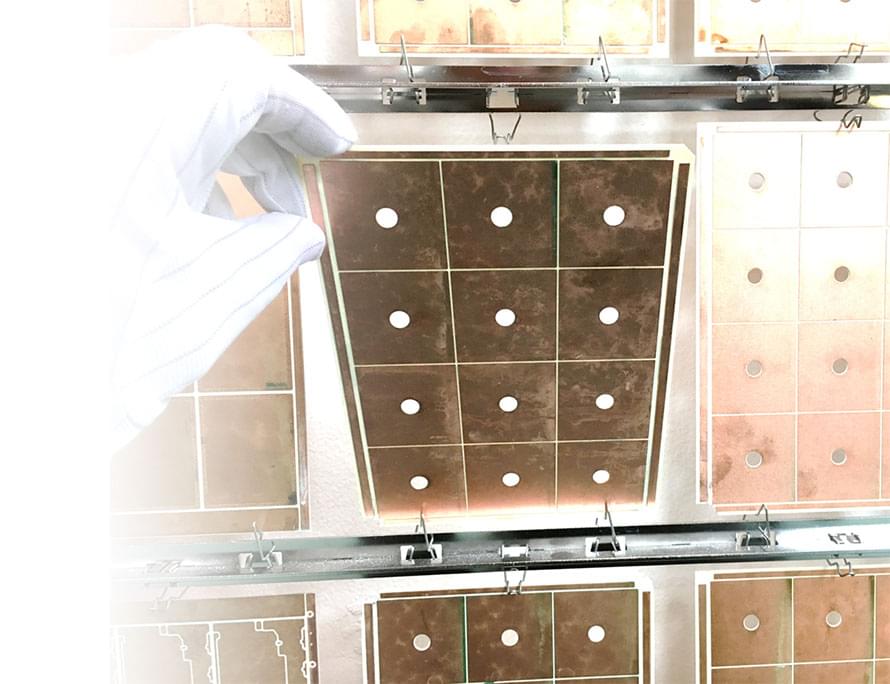

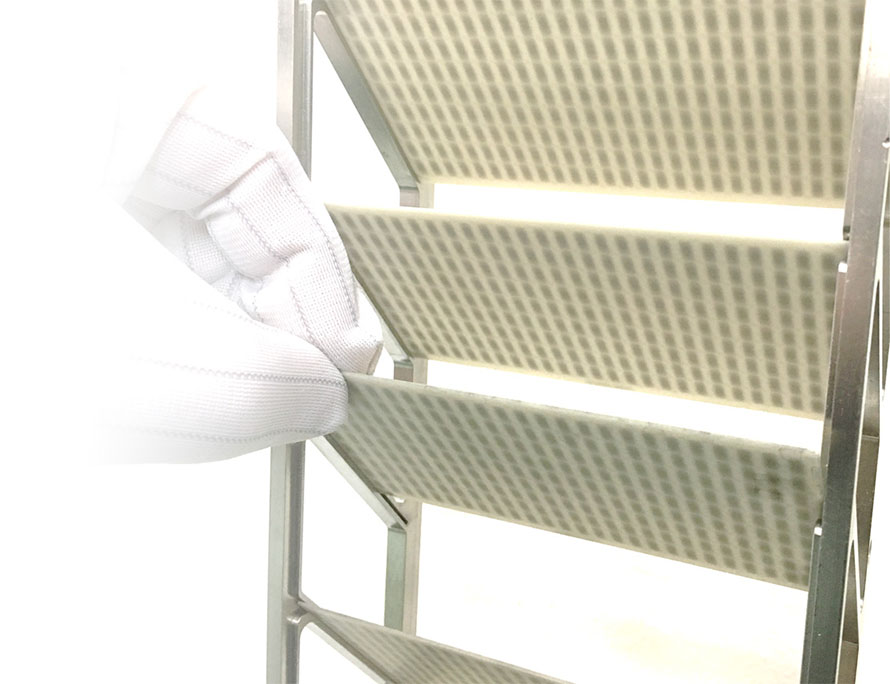

HORIZONTAL BARS WITH SPRINGS

- According to IPC 610, PCBAs shall be handled by the edges which are generally technologically missing

- PBT Works developed special springs for fixing which can be positioned precisely along the horizontal bars to gain perfectly balanced grip force

- Spring bars allow to fix wide range of products from small and light to large and heavy, even unusually shaped

- Bars are quickly and easily adjustable in vertical direction with no need of tool

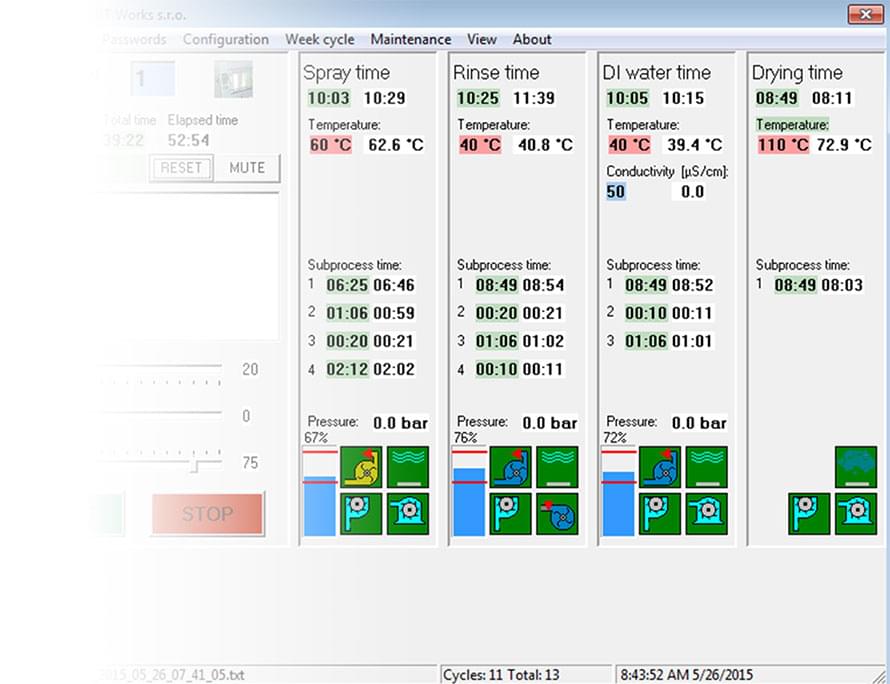

INTUITIVE TOUCHSCREEN INTERFACE

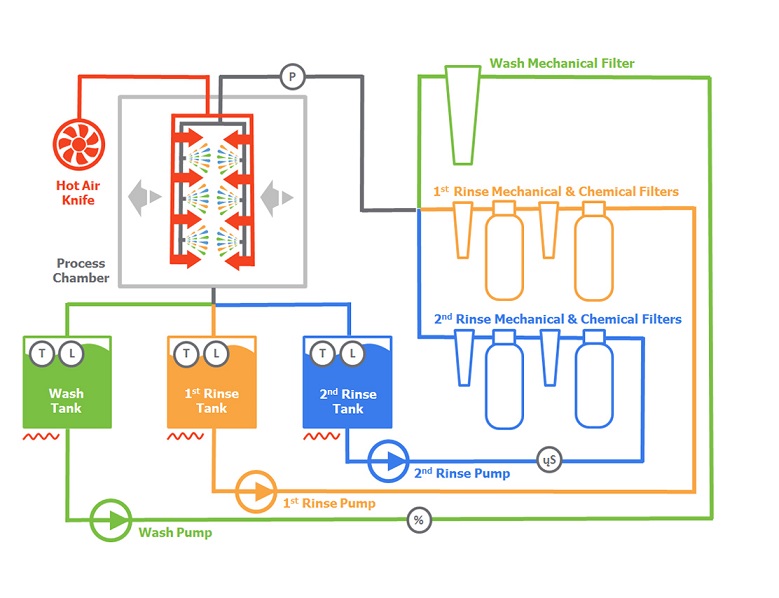

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters (time, temperature, pressure, conductivity-resistence, concentration etc.)

- Process steps may contain up to 5 substeps for perfect setup

- Indication of real level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Process messages, warnings and errors are clearly displayed

- All parameters and messages are saved on a simple log

- All process parameters can be easily viewed in graphs

- OS available in several different languages

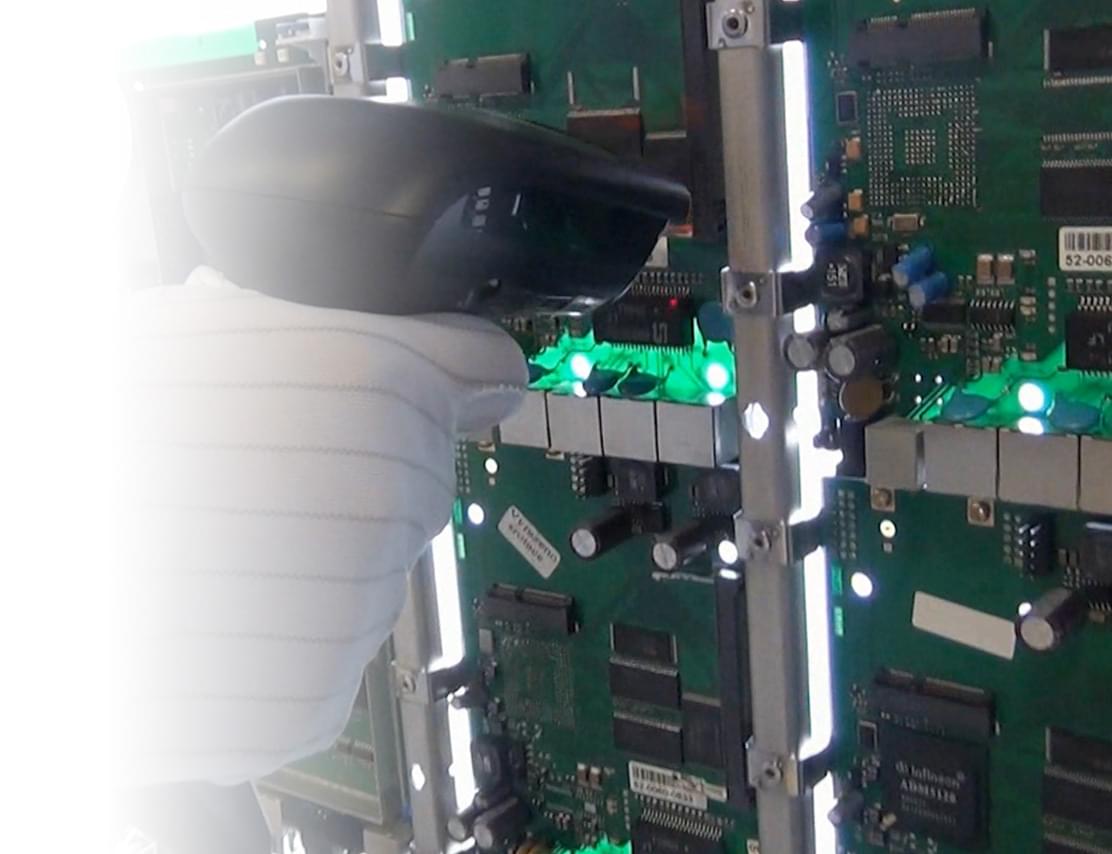

BAR CODE TRACEABILITY

- Barcode reader for product identification

- Automatic selection of cleaning program through barcode

- Complete archiving of barcodes with process parameters

- Traceability file created after each process with all set and real process data and messages, subsequently can be used in Manufacturing Execution System (MES)

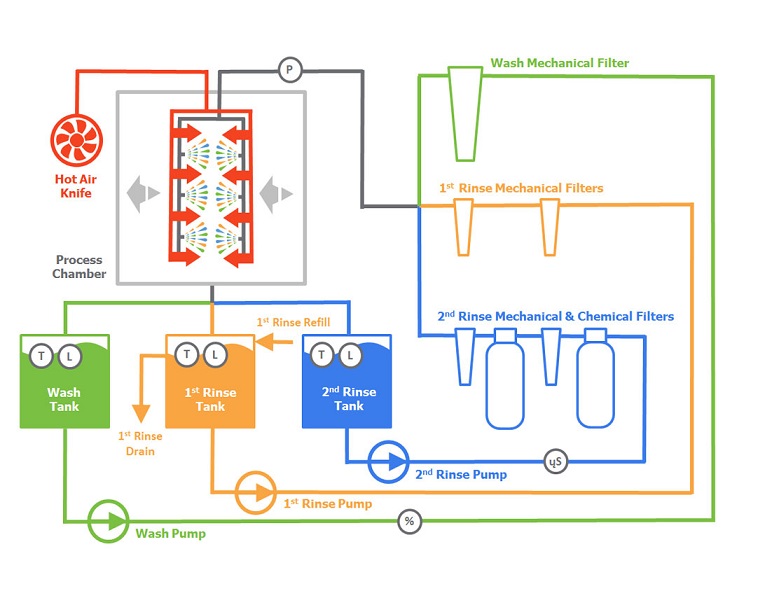

CONCENTRATION MONITORING ZESTRON® EYE

- Automated digital concentration monitoring system ZESTRON® EYE enables precise measurement and control in real time

- Proper concentration of chemicals in wash loop necessary for stable and reliable cleaning process

- Data from ZESTRON® EYE are fully integrated in the machine software

- Designed for ZESTRON cleaning agents

- Process parameters can be set and viewed on the unit touchscreen

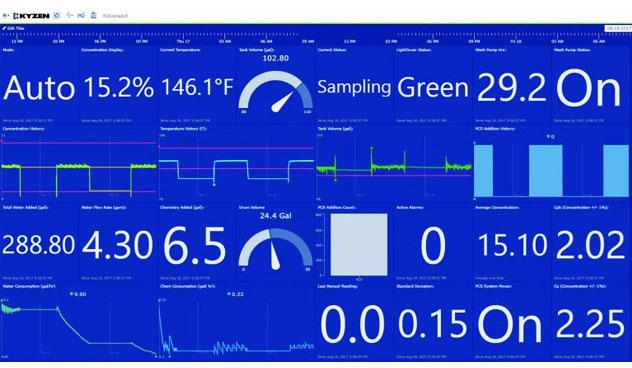

CONCENTRATION MONITORING KYZEN ANALYST™

- Real-time automatic concentration monitoring and reporting with KYZEN ANALYST™

- Stable and reliable cleaning process strongly depends on proper concentration of chemicals in wash loop

- Advanced data analytics system designed for all chemistries

- Data from KYZEN ANALYST™ are fully integrated in the machine software

- Process parameters can be set and viewed on the unit touchscreen

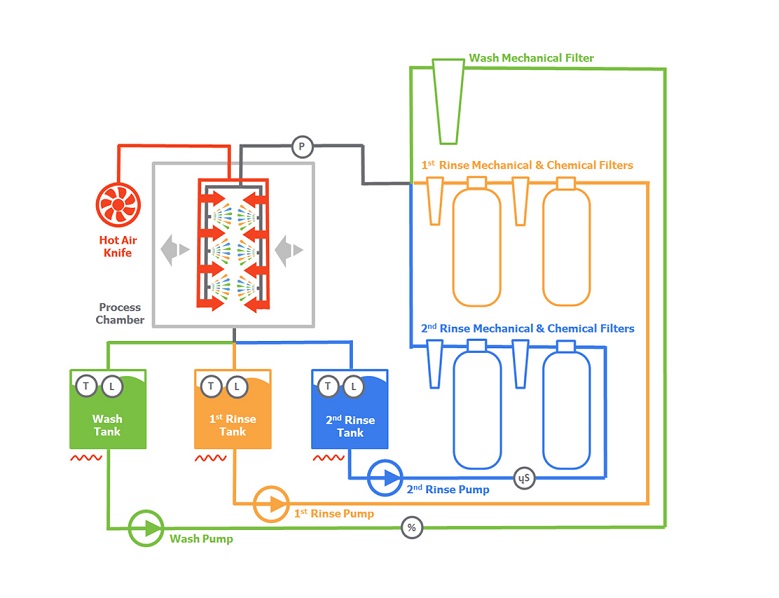

AUTOMATIC ADAPTIVE DOSING

- Applicable for absolute control of wash process

- Automatic system ensures stable concentration of cleaning agent

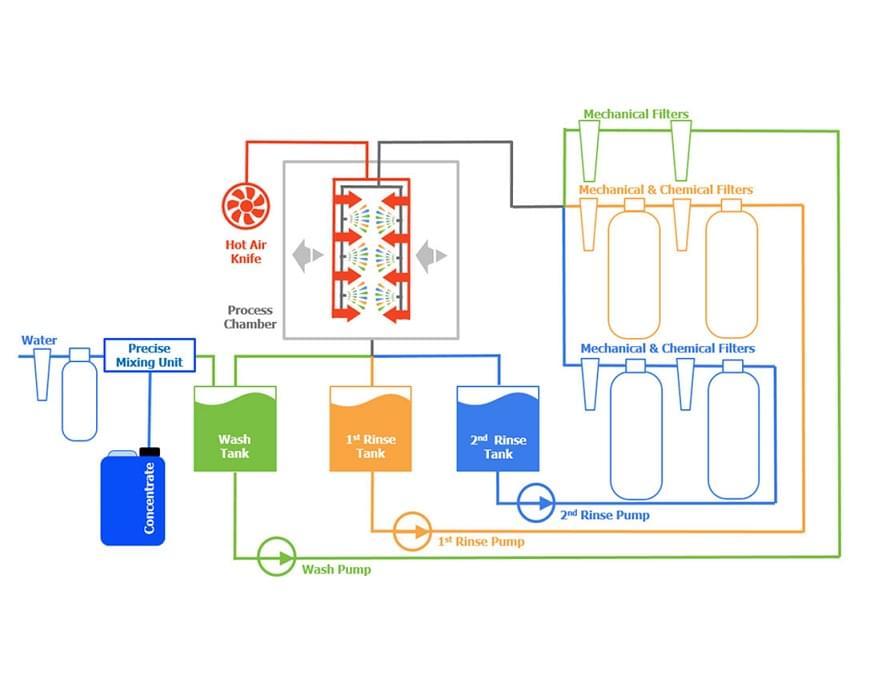

- The dosing unit refills the wash tank by pre-set concentration of the cleaning agent and DI water from external source or generated by the unit

- Adaptive concentration control and dosing unit utilizes integrated ZESTRON® EYE or KYZEN ANALYST™ monitoring