Relentless Multifunctional Pick and Place

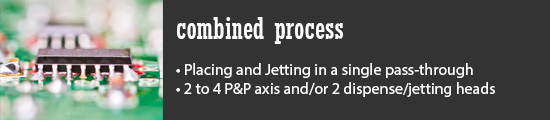

Introducing – The Paraquda – 3 in 1 multifunctional production center. The Paraquda SMD pick-and-place system is designed for low/mid volume or NPI (new product introduction) high-mix productions. The Paraquda combines three different production steps within one machine platform (solder paste jetting and/or glue jetting and SMD assembly).

| Paraquda2 | Prarquda4 | Para-Doble | ||

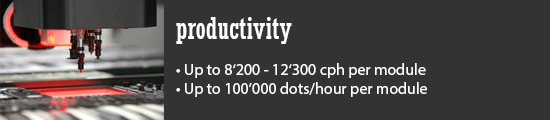

| Productivity | Optimum placement speed | 8’200 cph (2-axis) | 12’300 cph (4-axes) | 24’600 cph (2x 4-axes) |

| Optimum jetting speed | 100‘000 Dots/h | |||

| Feeder | Feeder Capacity 8 mm Tape | 240 (200 inline) | 240 (200 inline) | 400 inline |

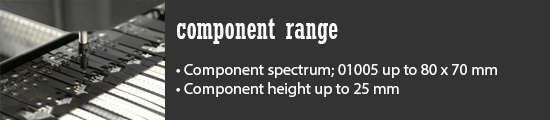

| Components | Component Size Range | 01005 up to 40×40 mm | (80 x 70 mm optional) | |

| Accuracy | Placement accuracy (x, y) | 51 μm @ 3σ | ||

| PCB | Max. PCB dimensions | 600 x 430 mm (23.6 x 16.9 ” ) | ||

| Dimensions | Machine footprint | 1300 x 1450 mm (51.2 x 57.1 ” ) | 1300 x 1450 mm (51.2 x 57.1 ” ) | 3040 x 1450 mm (118.1 x 57.1“) |

MULTITALENT SOFTWARE

AT YOUR FINGERTIPS

State of the art, full graphics, 21.5”, 16:9 HD wide touch screen, fingertip operation, universal CAD conversion,

zoom at camera windows, all-in-one job planning, setup optimisation, stock management, ERP/MES connection,

data analysis, line management and more.