PBT MINISWASH

PCB/STENCIL CLEANING MACHINE

APPLICATION

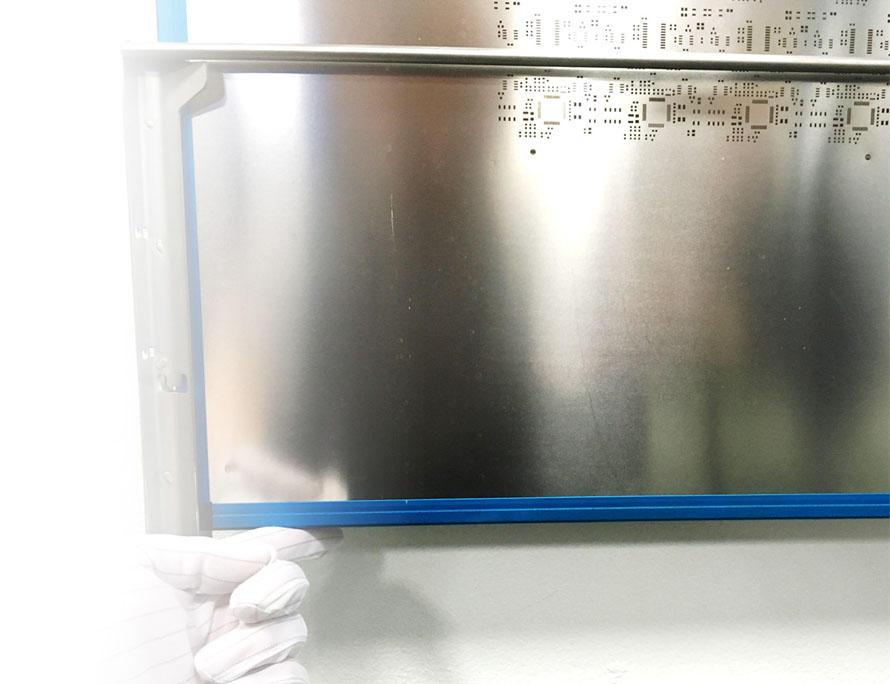

- Removing solder paste from any type of stencils, screens and printer squeegees

- Removing SMT Glue residues from any type of stencils, screens or PumpPrint stencils

- De fluxing, removing activators and resin residues, cleaning contamination from handling and board manufacturing

- Cleaning second side misprints on complex assemblies

CLEANING WITH MiniSWASH

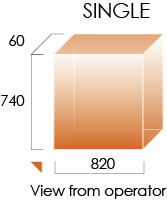

- Single frame configuration

- Closed loop zero drain system

- Rotary direct spray

- Hot air knife direct dry technology

- Anti-collision system

- Compatible with chemistry from various suppliers

- Small footprint

- Clamping for all types of stencils and squeegees

- Adjustable frame fixing system

- Wide range of PCBA fixtures

- Two fully separated liquid loops

- Low consumption of chemicals and water

- Outstanding options of water utilization

- Intuitive touchscreen interface

- PLC control

- Barcode traceability, LAN connectivity

- Adaptive rinse process control

- Multi language selection

USABLE SPACE OF CHAMBER

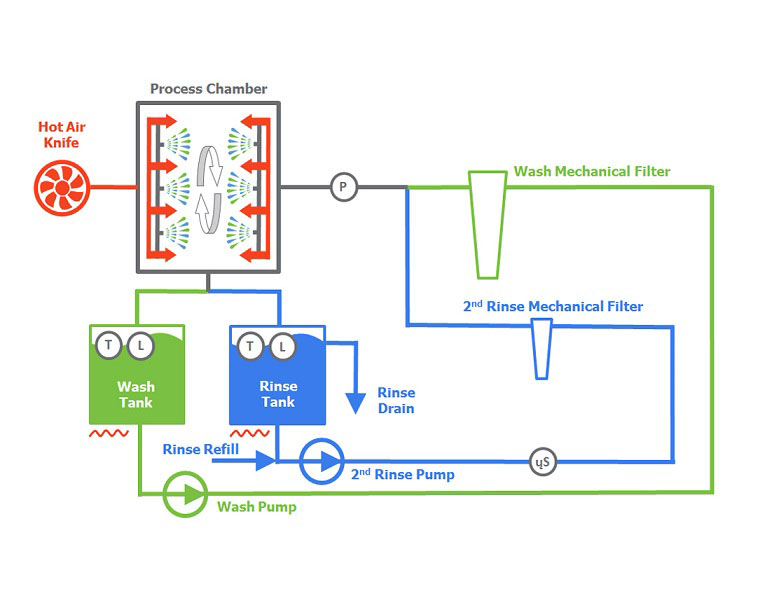

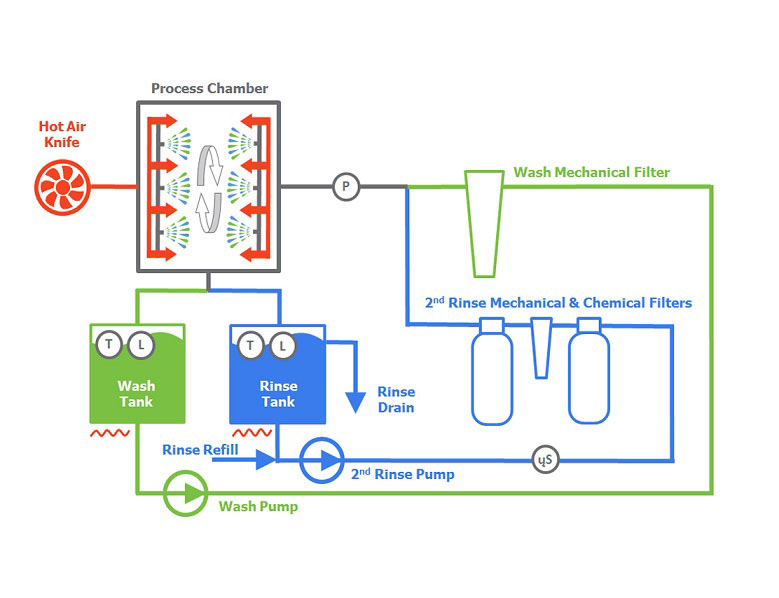

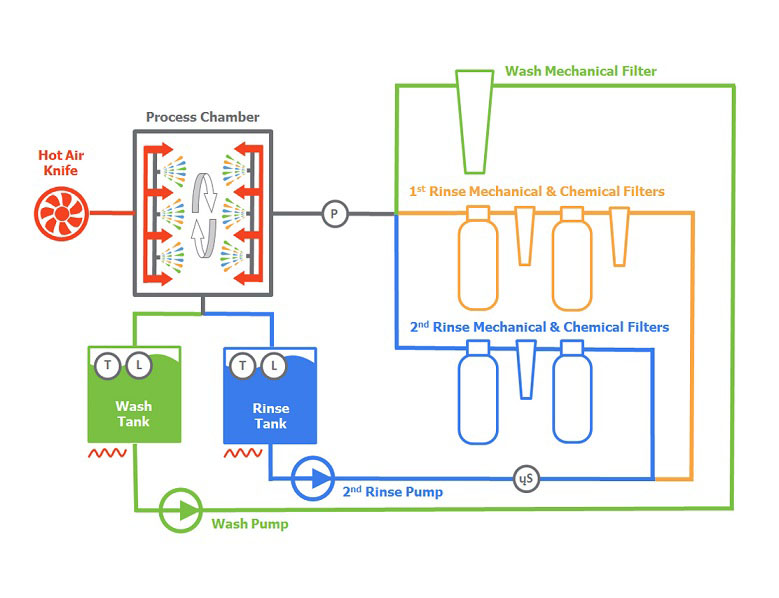

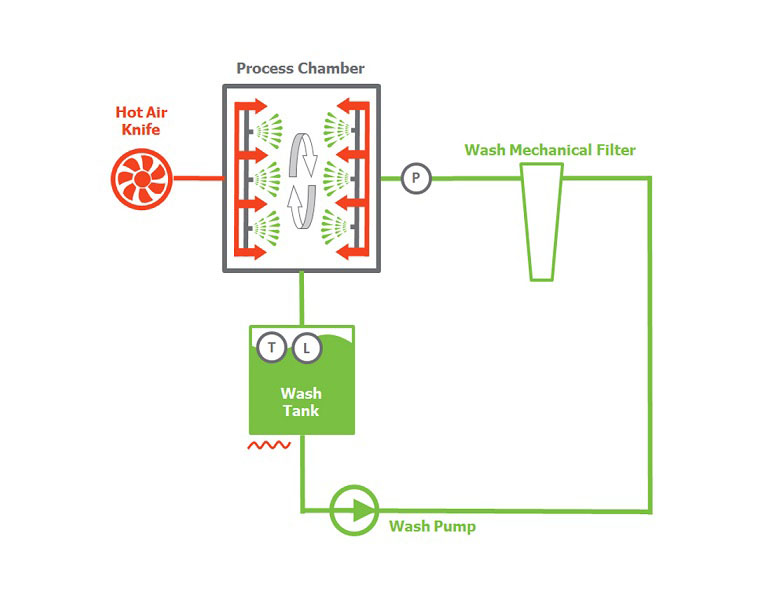

FILTRATION

- Developed to match modern cleaning agents

- Wash loop is closed and fully filtrated process

- Filtration extends the bath life to lower the process costs

- Various efficient ways of processing contaminated rinse loop water

- Rinse loops are flexible by design to meet various process and environmental requirements

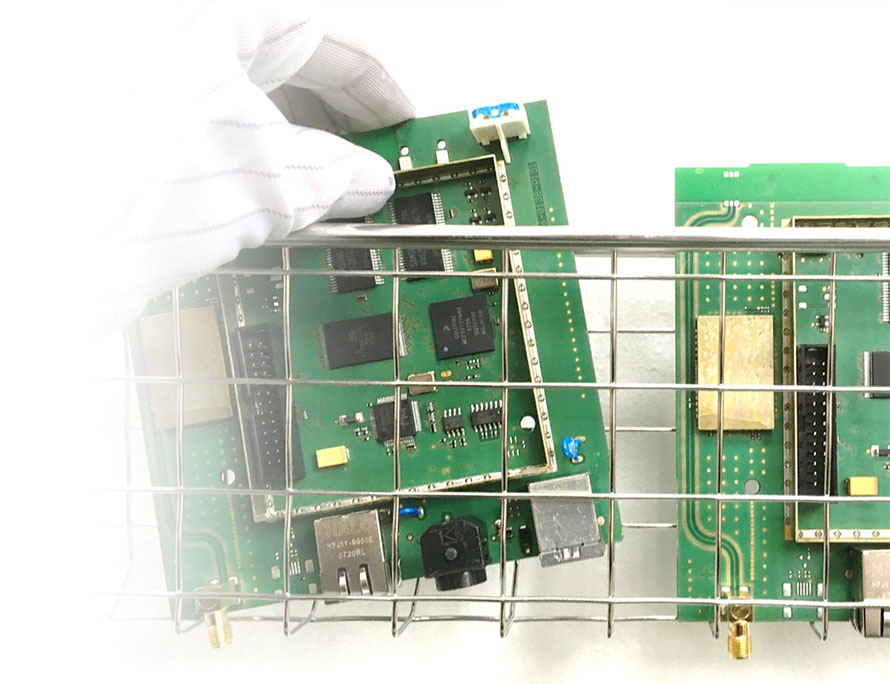

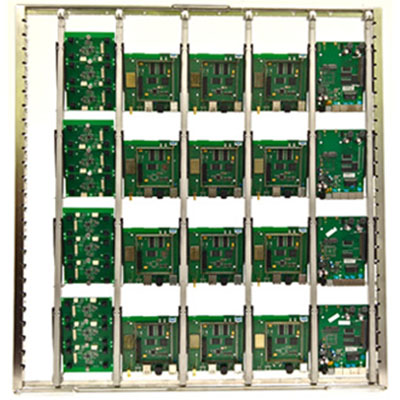

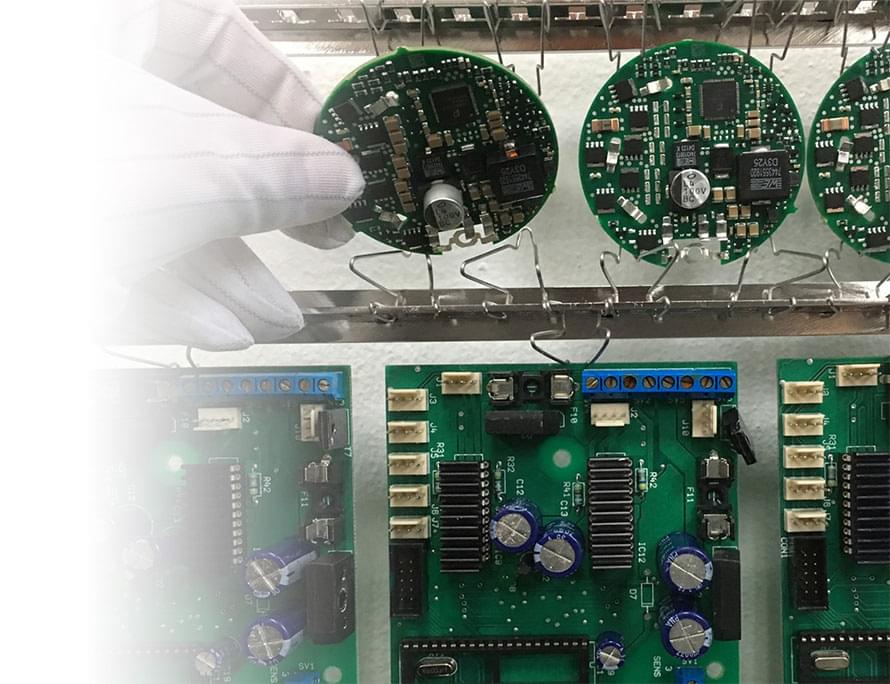

HORIZONTAL BARS WITH SPRINGS

- According to IPC 610 PCBAs shall be handled by the edges which are generally technologically missing

- PBT Works developed special springs for fixing which can be positioned precisely along the horizontal bars to gain perfectly balanced grip force

- Spring bars allow to fix wide range of products from small and light to large and heavy, even unusually shaped

- Bars are quickly and easily adjustable in vertical direction with no need of tool

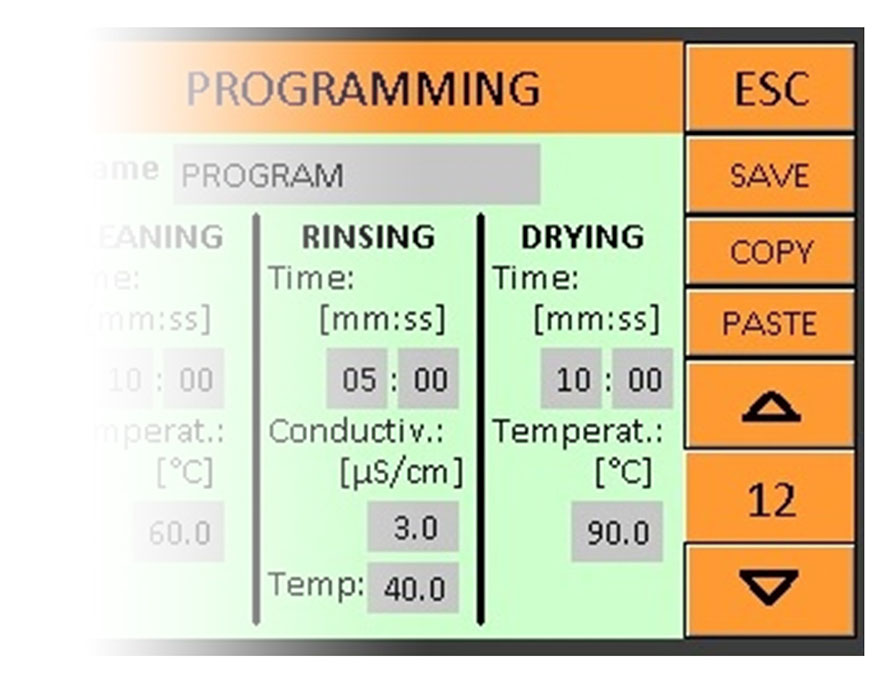

INTUITIVE TOUCHSCREEN INTERFACE

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters (time, temperature, pressure, conductivity-resistance)

- Indication of minimal level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Process messages, warnings and errors are clearly displayed

- OS available in several different languages